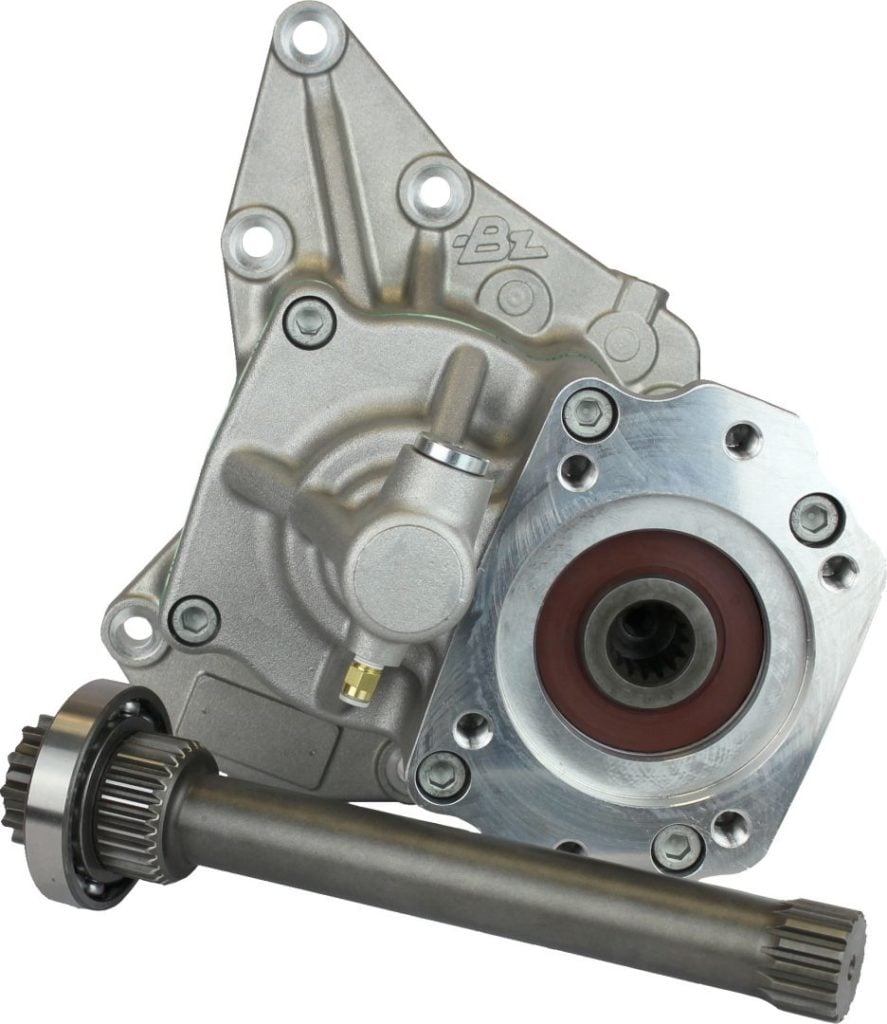

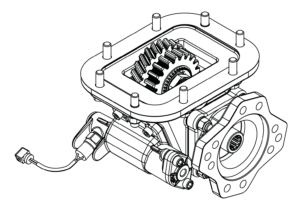

Welcome to the user manual of the Bezares 120x13DSB 120 Series Rear Mount Pneumatic PTO. This manual is designed to help you on the installation and usage of your PTO for the Detroit DT12 gearbox.

Additionally, this manual will guide you through the installation process, ensuring a perfect fit and straightforward installation of this rear-mounted PTO. This not only ensures seamless and efficient power transmission but also guarantees optimal performance of your auxiliary equipment.

The Bezares 120x13DSB PTO is the ideal solution for applications in construction, transportation, and other heavy-duty industries, meeting the highest standards of quality and reliability. By following this manual, you will ensure the optimal performance and longevity of your equipment.

How to select the correct shaft?

Check your gearbox model as follow:

DT12-DH1 /OH1 (& OLD P/N. DT12-DA /OA): Select 7018394

DT12-DH8 /OH8 (& OLD P/N. DT12-DB /OB): Select 700904

CAUTION

TO PREVENT POSSIBLE INJURY:

- DO NOT go underneath the vehicle with the engine running.

- DO NOT attempt to work on an installed Power Take-Off with the engine running.

- DO NOT operate the controls of the Power Take-Off or other driven equipment from underneath the vehicle with the engine running.

- DO NOT operate the controls of the Power Take-Off or other driven equipment in any position that could result in getting caught in the moving machinery.

Make sure to block any moving or raised device that may injure a person working on or under the truck. A lever or its linkage may be accidentally moved causing movement of the device which could cause injury to a person near the device.

IMPORTANT

Because most of our Bezares Power Take–Offs and P.T.O. drive lines are sold through distributors, the product applications and the resulting degree of exposure to danger of the operators are beyond the knowledge and controls of BEZARES.

Therefore, the proper installation of the P.T.O. and its associated equipment, and the decisions of whether to install guards and/or warning signs shall be the responsibility of the designers or installers.

Since it is our major objective to show you how to get additional and more profitable miles from truck, tractor and trailer components, we want to provide you with information on the installation of 1000, and 2000 Series.

We all realize that an inadequate transmission will overwork any Power Take–Off in a very short period of time. In addition, a mismatched transmission/P.T.O. combination can result in unsatisfactory performance of the equipment right from the start.

Before you order new trucks be sure that you’re getting the right transmission/P.T.O. combination. It is of vital importance for efficient performance to have adequate power.

To help you select the proper type, size and design of P.T.O. it is advisable to discuss your specific requirements with a Bezares P.T.O. specialist. They know their products and Power Take–Offs. They can inform you about everything you need to know about power, at the right time, before you specify components.

Here are some of the questions that are relevant to the Proper Selections of a Transmission mounted Power Take–Offs.

- What is the make and model of your transmission?

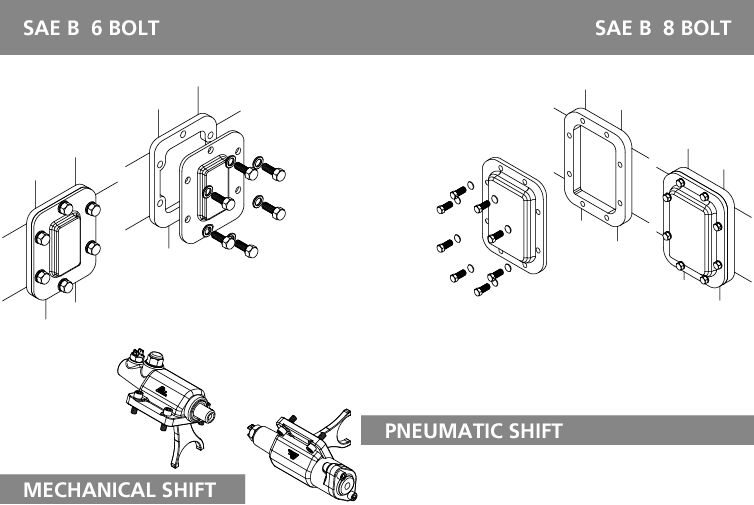

- Which P.T.O. opening will be used?

- What accessory is to be driven?

- How much horsepower is required to drive the accessory?

- What is the required rotation of the P.T.O.?

- What is the required P.T.O. output shaft speed as a percent of engine speed?.

- What is the required method of shifting the P.T.O., mechanical or pneumatic?

Once all of the answer to these questions have been determined, a transmission mounted P.T.O. can be selected to meet the horsepower, speed and rotation that you require.

Check out our PTO Selection form at bezares.com/pto-selection-tool/

Having made the selection of a P.T.O., you are ready to start the installation.

Drain the oil from the transmission and the P.T.O. aperture cover plate.

Discard the cover plate and cover plate gasket then clean the aperture pad using a putty knife or wire brush.

NOTE: Stuff a rag in the aperture opening to prevent dirt from entering the transmission while you are cleaning it.

Using your hand, rock the P.T.O. driver gear in the transmission and the driven gear in the P.T.O. assembly. Rocking the gears provides two important factors:

A.- The amount of backlash that has been designed into each unit.

B.- Helps establishing the proper backlash when installing the P.T.O.

Install the proper studs (furnished with P.T.O.) in the P.T.O. aperture pad using a stud driver. Studs may have either interference fit threads (plain) or preapplied locking/sealing compound.

Secure P.T.O. to the transmission .

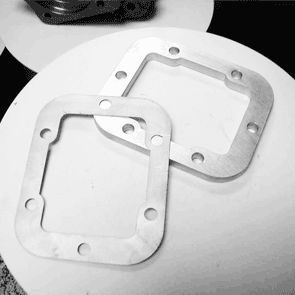

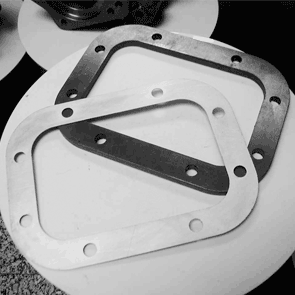

Gaskets are used as a guard against leaks under cap screw head.

NOTE: If holes in the P.T.O. aperture are not drilled through, discard the gaskets and replace them with lock washers.

Tighten studs securely and torque to 17-19 Ft. lbs. (2.35-2.63 kg meters) for 6 bolt and 19-21 Ft. Lbs. (2.63-2.90 kg. meters) for 8 bolt.

Place the correct number of gaskets over studs. Do not use paste between gaskets because you may want to add or subtract gasket to obtain proper backlash.

- When mounting a P.T.O. use gaskets between all mounting surfaces.

- Do not stack more than 3 gaskets together.

- Usually one thick gaskets 0.020” (0.50 mm) will be required.

- Remember the lubricant in the P.T.O. Therefore. At least one gaskets must always be used on either side filler blocks, adapter assemblies or adapter plates. More gaskets may be required when establishing proper backlash.

Secure P.T.O. to the transmission .

Gaskets are used as a guard against leaks under cap screw head.

NOTE: If holes in the P.T.O. aperture are not drilled through, discard the gaskets and replace them with lock washers.

Secure P.T.O. to the transmission .

Gaskets are used as a guard against leaks under cap screw head.

NOTE: If holes in the P.T.O. aperture are not drilled through, discard the gaskets and replace them with lock washers.

Caution

Overtightening of studs may damage stud and / or transmission threads.

Remove the P.T.O. shift housing and/or inspection plate.

Mount the dial indicator so that it registers movement of the input gear (driven gear) of the P.T.O.

NOTE: See drawing for proper location of dial indicator contact point. (Two common methods of dial indicators shown.)

Hold the P.T.O. driver gear in transmission with a screwdriver or bar and rock the P.T.O. input gear (driven gear) back and forth with your hand.

Note the total movement on the dial indicator.

Establish backlash at 0.006” – 0.012” (0.15 mm-0.30mm) by adding or subtracting gaskets.

General rule – A Bezares 0.010” gaskets will change backlash approx. 0.006”. A 0.020” gaskets changes backlash approx. 0.012”.

Replace the shift housing and/or inspection plate and retorque (4) four capscrews to 16-20 Ft. Lbs. (2.21-2.76 kg meters).

CAUTION

This vehicle is equipped with a Power Take-off.

Shut engine off before working on Power Take-Off or getting below vehicle.

Consult operating instructions before using.

POWER TAKE-OFF OPERATION VEHICLE STATIONARY.

- Mechanical Transmission.

A power take-off is, and should be, operated as an integral part of the main transmission.

Before shifting the power take-off into or our of gear, disengage the clutch and wait for transmission or P.T.O. gears to stop rotating. - Automatic transmission with manual shift P.T.O. (Includes air shift).

On automatic transmissions, the gears in the transmission turn when the transmission is in neutral, therefore, gear clashing will ocurr if the power take-off is shifted into gear at this time.

With converter driven gear:

• Shift transmission lever into any of drive positions. (This will stop the transmission gear from turning).

• Shift power take-off into gear.

Shift transmission into neutral. (This will start transmission gears turning.)

• Shift P.T.O. into gear before starting engine.

This procedure should eliminate gear clash. - Automatic transmission with power shift P.T.O’s

Engage P.T.O. with engine at idle speed. Power shift P.T.O.´s: engine must be at idle when P.T.O. is engaged. See transmission manufacture´s instructions for special procedures.

IMPORTANT

Failures to follow proper shifting or operating sequences will result in premature P.T.O. failure with possible damage to other equipment.

1000/2000 SERIES PTO TOOL LIST

- Impact wrench

- 32 oz. ball peen hammer

- 16 oz. dead blow mallet

- Nail set punch

- 5/32” line up punch

- Pitman arm puller w/socket to fit drive nut

- 19mm socket

- 17mm combination wrench (modified/speed)

- 1-7/16” open end wrench

- M12-1.75” Stud Installation Socket

- Loctite – Thread Grade

- Loctite – Bearing Grade

- Bench vise

- Large flat blade screw driver

- 3mm double sided t-handle (recommend Matco TXM3)

- Snap ring pliers – large & small

- Tack puller (recommend Great Neck TL4C)

- Bernzomatic torch loaded preferably with MAPP gas.

- 3/32” pop rivet tool

- Automotive High-temp. assembly grease

- WD-40

- Nameplate Stamping Machine or Die Stamps

- ½” Stud Extractor Socket

- Seal Puller

- 6mm Hex Bit Socket

- 1-1/4” Socket

- Hydraulic Press

- 70mm OD Press Tool

- 28mm OD Press Tool

- 25mm OD Press Tool

- 51mm ID Press Tool

- 36mm ID Press Tool

- 60mm OD Press Tool

- 26mm ID Press Tool

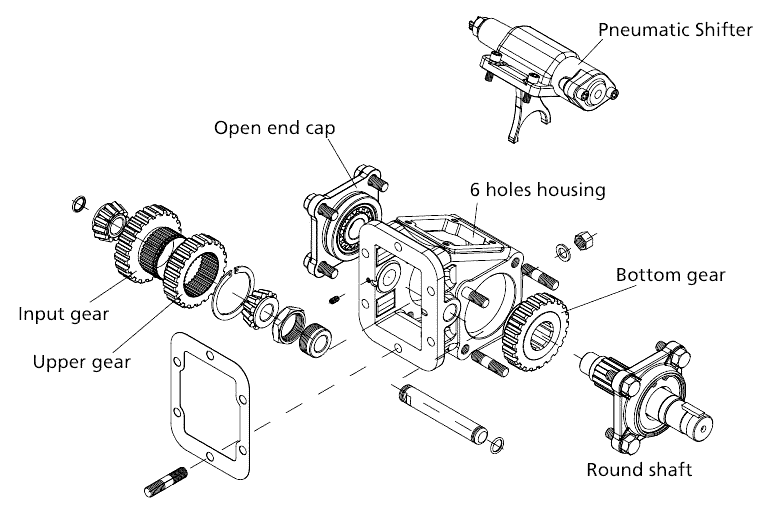

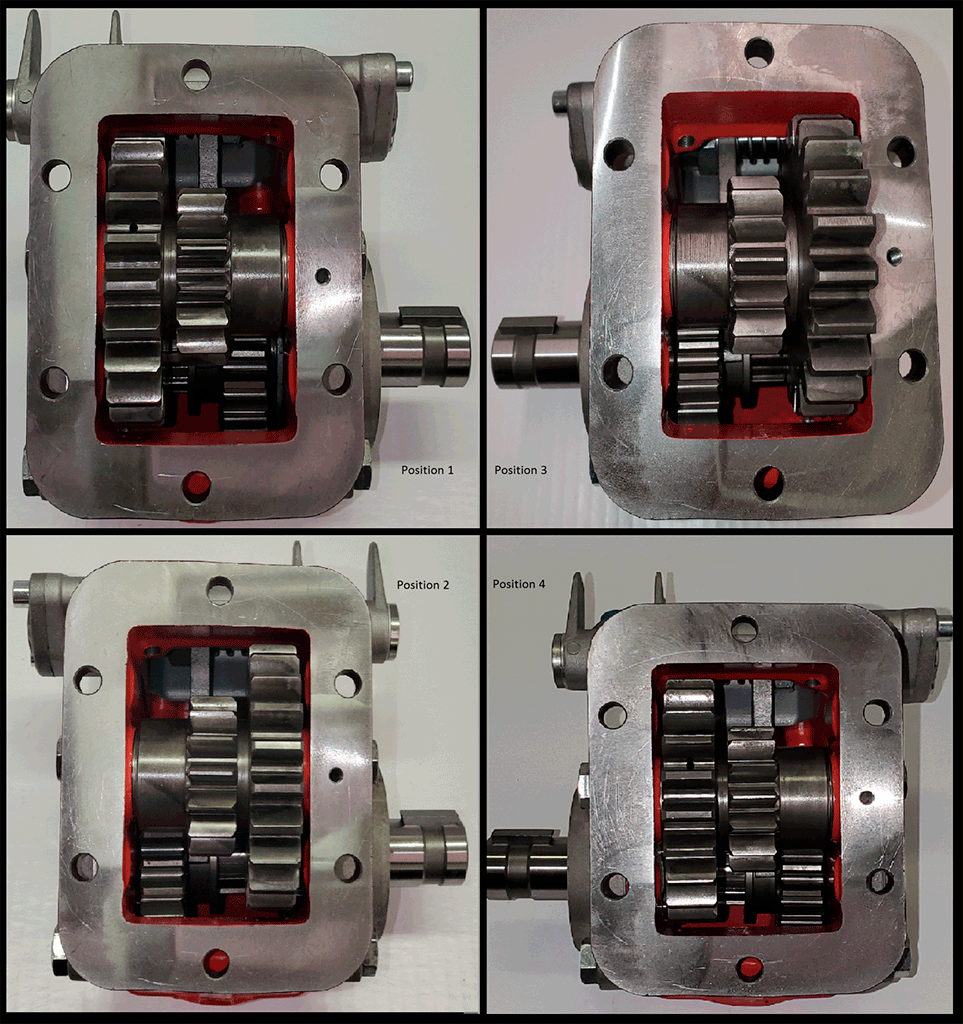

Assembly Procedure for 1000/1010/2000/2010

Determine product arrangement and position accordingly.

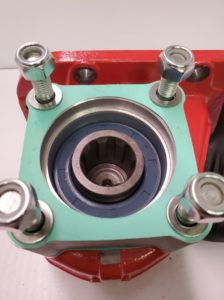

Use an M12-1.75 stud installation tool to install studs into the housing at approx. 25ft-lb when necessary for direct mount or adapted outputs. Ensure that the threaded end with loctite is inserted into the housing.

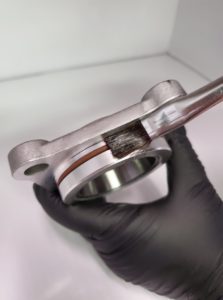

Install the snap ring onto the output shaft with snap ring pliers.

Press the output bearing onto the shaft up to the snap ring with 36mm ID tool. For Din output, press the output bearing onto the shaft up to the shoulder with 51mm ID tool.

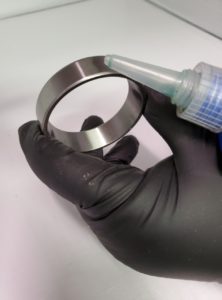

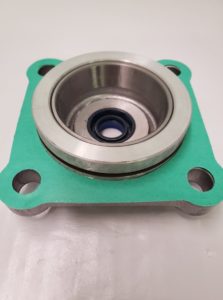

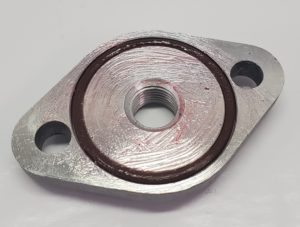

Apply Bearing Grade Loctite to the end cover bearing race. Install the o ring to the end cover and apply assembly grease to the o ring diameter.

Press the end cover bearing race into the end cover with 60mm ID tool. Place the end cover gasket onto the end cover aligning the bolt holes.

Assembly for greasable output

Apply assembly grease to seal diameter of greaseable end cover and o ring. Install o ring and press the greaseable seal into the end cover with 28mm OD tool.

Install bearing race with 60mm OD tool and place end cover gasket onto the end cover. Insert the seal protector into the end cover over the greaseable port in the output shaft manually.

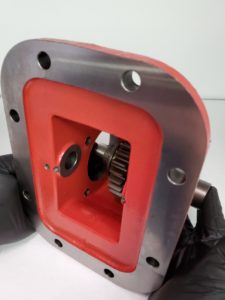

While holding the internal ratio gear in the housing, pass the output shaft through the gear noting position of parts per current arrangement.

Place the end cover bearing onto the end of the output shaft and press it up to the shoulder with 26mm ID tool.

Place the end cover on the end cover bearing side of the housing and tap it in with a dead blow mallet until it seats fully while aligning the bolt holes. Install bolts and washers with 19mm socket to approx. 25ft-lb.

Apply Bearing Grade Loctite to the output bearing race and press it into the housing manually to support the output shaft. A few light taps with a mallet will help to seat it.

Assembly For RA Output (2/4 bolt B flange)

Quality control check #1. Spin and pull the output shaft checking resistance and tolerance for radial and linear preload. Use a thinner end cover gasket under the end cover and/or the output flange if tolerance is loose. Install an additional gasket under the end cover if the tolerance is too tight.

Tap the wrench or use a torque wrench to fully tighten the lock nuts to approx. 25ft-lb.

Place an end cover gasket over the flange studs and tap the flange into position over the output shaft. Place nuts and washers over the studs and tighten down the flange with 17mm speed wrench.

Apply assembly grease to seal diameter of output flange. Press the seal into the flange up to the shoulder with 70mm ID tool and install the snap ring into the groove in the flange. Position the weep hole in the flange to the furthest point from the shifter opening based on arrangement.

Assembly For DIN Output (4 bolt)

Apply assembly grease to seal diameter of output flange. Press the seal into the flange up to the shoulder with 70mm OD tool and install the snap ring into the groove in the flange.

Tap the flange into place with a gasket over the output bearing and output shaft while aligning the bolt holes. Install bolts and washers with 19mm socket to tighten flange to approx. 25ft-lb. Place a key in the keyway and wrap shaft with tape to secure.

Quality control check #1. Spin and pull the output shaft checking resistance and tolerance for radial and linear preload.

Assembly For SE Output (1-1/4” Keyed Shaft)

Apply assembly grease to the seal diameter of output flange.

Press the seal into the flange up to the shoulder with 70mm OD tool and place an output gasket over the studs. Tap the flange into place over the output bearing and output shaft. Install an output gasket, nuts, and washers over the studs.

Quality control check #1. Spin and pull the output shaft checking resistance and tolerance for radial and linear preload.

Place a shifter gasket on the fully assembled shifter while aligning the mounting holes. Install the shifter into the shifter opening in the housing while aligning the shifter fork with the groove in the internal gear. Install backlash tag and shifter retaining screws manually with a flat head screw driver. For manul shifter, follow same procedures for air shifter, and manually shift the lever to ensure proper shifter engagement.

Assembly Procedure for 1000/1010/2000/2010

Apply thread grade loctite to the preload nut and place it on the thrust washer.

Place the ratio gear onto the splines of the input gear and install the snap ring. Apply assembly grease to the thrust washer and install it over the idler bearings within the gear.

Install backlash tag and shifter retaining screws manually with a flat head screw driver.

Insert the gear stack into the input opening in the housing.

Install o rings into the grooves in the idler pin and apply assembly grease to the diameters of the o rings. Use 100 grit emery cloth to deburr the set screw port in the idler passage. Align the machined flat in the idler pin with the set screw port in the housing.

Install a snap ring to the top end of the idler pin and drive the idler pin through the gear stack at approx. 850psi with 25mm OD tool aligning all components in the housing up to the snap ring on the pin.

Ensure the idler pin o rings are not damaged or extruded beyond the housing. Install a snap ring onto the opposite end of the idler pin.

Apply thread grade loctite to the set screw and install it into the set screw port in the housing until fully seated against the idler pin machined flat with a 3mm hex bit.

Insert a 3/16” pin bar into the opening in the preload nut and leverage it against the housing. Apply WD40 to the preload bearings and tap the gear with a mallet to fully seat the preload stack. Tighten the preload nut with a 1-7/16” wrench until desired resistance is found in the preload bearings.

The gears must spin freely without coasting and must make no noise or contact any other part of the assembly. Use a pin punch to pierce the indent in the preload locking nut.

Quality control check #2. Spin the input gear stack to test for proper preload resistance.

P.T.O. Assembly for Unigear input

Insert the needle bearings into the input gear with the spacer between them. Hang tab washers in the hosuing idler grooves and insert the gear stack into the housing.

Drive the idler pin through the gear stack at approx. 850psi with 25mm OD tool aligning all components in the housing up to the snap ring on the pin.

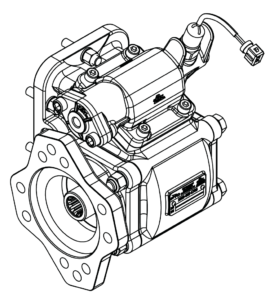

P.T.O. Assemlby for Din Adapted output

Place an end cover gasket over the Din studs, install the stub shaft or bearing assembly into the Din shaft, place the output flange over the bearing, and install nuts and washers onto the output studs with 17mm socket to approx. 25ft-lb.

Install outer flange if applicable and tighten to approx. 25ft-lb. with 19mm socket. Do not install a seal to the Din flange when using an adapter that contains an output bearing.

Quality control check #3. Apply air pressure (recommended 100psi) to the port in the air shifter several times to check for leaks and proper gear engagement.

Install an ID Plate with two rivets with the top of the tag toward the shifter. The tag must include product part number and a serial number containing a builder code.

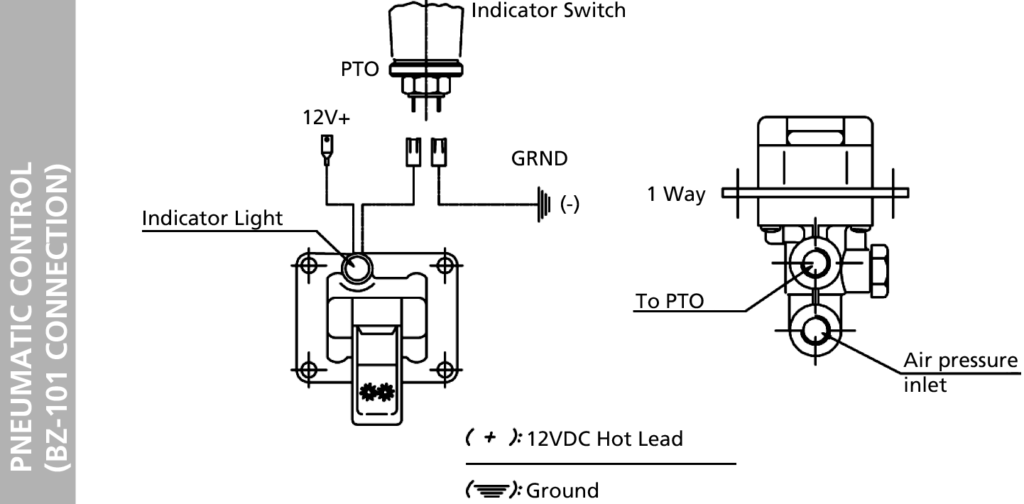

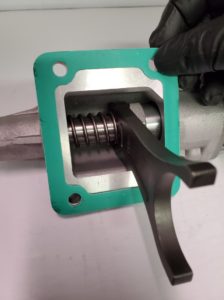

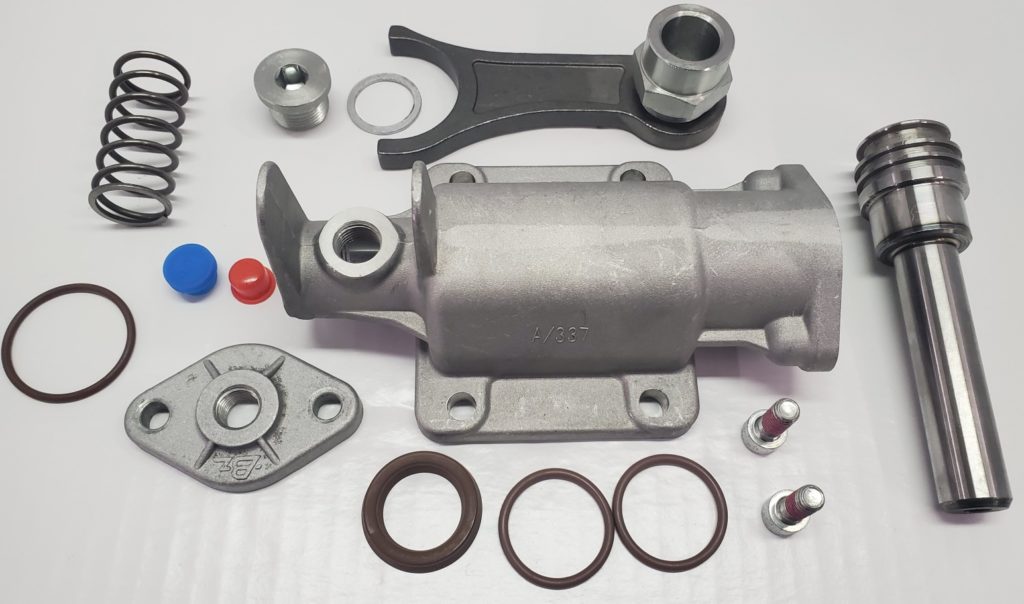

Air Shifter Assemlby

Determine product arrangement and position according to PTO code. Apply thread grade loctite to the end plug and install it and the washer with an M8 hex bit at approx. 25ft-lb into the end of the shifter housing.

Apply thread grade loctite to the fork bushing threads and install it in the fork with 1-1/4” socket to approx. 25ft-lb. considering shifter arrangement.

Insert the fork with bushing and the spring into place in the shifter housing considering shifter arrangement.

Install the o rings and seal onto the shifter piston and apply assembly grease to the seal diameters. Insert the piston into the housing and through the spring and bushing.

Compress the spring by pushing the piston flush into the housing. Install the end cover o ring and apply assmebly grease to the diameter.

Place the end cover over the piston on the end of the shifter and install the two end cover bolts with an M6 hex bit tightening to approx. 25ft-lb. Install the plastic plugs into the shifter ports.

Quality Control Check #1. Apply air pressure (recommended 100psi) to the end port to activate the piston checking for full stroke and leaks.

PTO Troubleshooting

| wdt_ID | PROBLEM | REASON | CORRECTIVE ACTION | PREVENTION |

|---|---|---|---|---|

| 1 | PTO is Noisy (whines) | -insufficient mounting backlash | -remount PTO adding gaskets to achieve backlash of .006-.012” | -check and set proper backlash |

| 2 | PTO is Noisy (rattles) | -excessive mounting backlash | -remount PTO removing gaskets to achieve backlash of .006-.012” | -check and set proper backlash |

| 3 | PTO is Noisy (clicks) | -damaged/worn gear tooth | -replace damaged/worn gear | -check and set proper backlash |

| 4 | -overloading PTO | -reduce load | -review application | |

| 5 | Leaking Shaft Seal | -dirt under seal | -replace seal | -preventive maintenance |

| 6 | -damaged seal or cover | -replace seal or cover | -preventive maintenance | |

| 7 | -improperly seated seal | -replace seal | -preventive maintenance | |

| 8 | -worn shaft at seal area | -replace output shaft/seal | -preventive maintenance | |

| 9 | Leaking Output Flange | -torn flange gasket | -replace gasket | -preventive maintenance |

| 10 | -loose flange bolts | -properly torque flange bolts | -preventive maintenance | |

| 11 | -direct mount pump improperly supported | -install pump support brackets | -review application requirements | |

| 12 | Leaking Mounting Face | -torn mounting gasket | -replace mounting gasket | -preventative maintenance |

| 13 | -cracked mounting pad | -replace housing/set backlash | -proper mounting torque | |

| 14 | -broken mounting shim | -replace mounting shim/set backlash | -preventative maintenance | |

| 15 | -improper gaskets/shim used | -replace gaskets/shim | -ensure proper gaskets/shim are used | |

| 16 | Leaking Bearing/Shift | -torn gasket | -replace gasket | -preventive maintenance |

| 17 | COVER | -loose cap screws | -properly torque cap screws | -preventive maintenance |

| 18 | Cracked Housing | -insufficient backlash | -replace housing/set backlash | -check and set proper backlash |

| 19 | -unsupported direct mount pump | -replace housing/attach pump support bracket | -review application | |

| 20 | -over torque condition | -replace housing | -review application | |

| 21 | -foreign object between gears | -replace housing/gears | -preventive maintenance | |

| 22 | -impact with external object | -replace housing | -install protection/avoid impacts | |

| 23 | -shock load/cold relief pressure | -replace housing | -allow oil to warm before loading | |

| 24 | PTO Failure | -broken/damaged parts | -inspect/replace damaged parts | -preventive maintenance |

| 25 | -driveshaft problem | -check phasing, angle, and slip of driveshaft | -preventive maintenance | |

| 26 | -worn/damaged driveshaft components | -repair/replace driveshaft | -preventive maintenance | |

| 27 | PTO Does Not Engage/ Disengage (wire shift) | -worn/damaged shift control | -repair/replace components | -preventive maintenance |

| 28 | -loose/missing linkage/attachments | -adjust/replace components | -preventive maintenance | |

| 29 | -worn/damaged cable | -repair/replace components | -preventive maintenance | |

| 30 | PTO Does Not Engage/ Disengage (air shift) | -lack of air pressure | -ensure pressure exceeds 100psi/governor cut-in | -preventive maintenance |

| 31 | -shifter damaged | -replace shifter | -install protection/avoid impacts | |

| 32 | -shifter piston leaking | -replace shifter seals | -preventive maintenance | |

| 33 | -shifter piston does not move | -check for contaminates in air cylinder | -preventive maintenance | |

| 34 | -contaminated air lines | -clean air systems | -preventive maintenance | |

| 35 | -worn/damaged shift control | -repair/replace components | -preventive maintenance | |

| 36 | PTO Does Not Engage/ Disengage (all) | -shift fork not in shift collar | -check/reinstall shift cover | -preventive maintenance |

| 37 | -internal gears do not mesh | -check for internal debris/damage | -preventive maintenance | |

| 38 | -improper shifting | -adjust vehicle clutch | -review transmission manual |