Bezares, a leading company in the manufacture of hydraulic elements, has acquired a new TTL series lathe from CMZ with the aim of improving its production. This project has been co-financed by the Center for Industrial Technological Development, E.P.E. (CDTI-E.P.E.), a Public Business Entity under the Ministry of Science, Innovation and Universities, which promotes innovation and technological development of Spanish companies. The CMZ TTL series lathe is a machine that…

This year has brought unexpected challenges for our business and our employees, and we thank you for all the effort and commitment you’ve shown as we adjusted in tough times. We wish you the very happiest and most peaceful of holidays and look forward to a new year full of wins and successes big and small.

Bezares continues to make progress in its Digitization 2.0 project, in this spirit and to make life easier for our customers, we continue to add new tools to our portals in Spain and globally. Apart from many new internal tools, the latest customer-facing development is a system designed to easily check the status of all the orders they have in Bezares in the customer area. This new tool is added…

In its commitment to the environment and to reducing emissions, Bezares has just improved the heating system to get ready for a hard winter with possible gas shortages. After more than 10 years using heating from renewable sources, Bezares has adapted its thermal system to increase its efficiency, resulting in improved consumption and a significant reduction in system emissions. This new measure adds to the electric vehicles already in the…

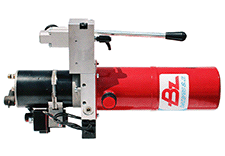

We at Bezares are proud to summarize our successful participation at the world’s leading trade fair, Bauma 2022 were we presented our latest hydraulic developments. In this edition, the focus was on a wide variety of future topics in the construction, building materials and mining machinery industries where Bezares presented its latest developments in hydraulic pumps and motors as well as new PTOs.