Differences Between Hydraulic Pumps and Hydraulic Motors: A Bezares Product Guide

In the field of mobile or industrial hydraulics, both hydraulic pumps and motors are critical components for the proper functioning of various applications. These two products, often outwardly similar, perform different yet complementary functions.

This article aims to provide a simple overview, given the variety of technologies that can be found in this field.

What is a hydraulic pump?

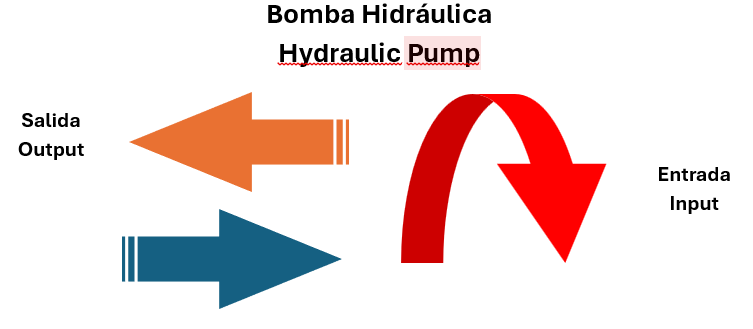

A hydraulic pump converts the mechanical energy from the vehicle’s engine into hydraulic energy, driving hydraulic fluid through a pressure line to the device that needs to be operated (valves, hydraulic cylinders, hydraulic winches, etc.). Since they are responsible for generating pressure in the circuit, we can say that without the hydraulic pump, it is not possible to have a medium or high-pressure hydraulic circuit.

How does a hydraulic pump work?

Hydraulic pumps work by moving fluid from a low-pressure area to a high-pressure area, generating the flow and pressure needed to serve a hydraulic application. Each type of hydraulic pump (hand pump, gear pump, vane pump, or piston pump) offers specific performance in terms of maximum pressure and/or speed, which determines which applications each type is best suited for.

Most common types of hydraulic pumps

- Gear Pumps: Known for their simplicity and lower cost, widely used for medium and low-pressure applications. Bezares offers a complete range of gear pumps with different flow rates, segmented into various sizes (BEA, BEM, BEL, BEX), recognized for their reliability and durability in diverse environments.

- Vane Pumps: Their main features are modularity and lower noise levels. They offer smooth operation and a constant flow, making them suitable for medium-pressure applications. Bezares’ Series D and V vane pumps are designed to achieve excellent efficiency and performance for most industrial applications.

- Piston Pumps: Highly efficient and capable of handling high-pressure tasks with compact dimensions, making them manageable and avoiding vehicle interference. Bezares manufactures its MR Series (medium-duty) and FR Series (heavy-duty) pumps, designed to deliver exceptional performance in demanding environments. Additionally, our FR2 Series, with dual flow, provides solutions for applications requiring three different flows in a single circuit, while the FRV 84 Series offers variable displacement, providing versatility in applications that require precise control over flow and pressure.

- Hand Pumps: Used in low-pressure circuits, they can serve as an auxiliary emergency method in case of main power supply failure. Bezares offers single and double-acting hand pumps with various displacements.

What is a hydraulic motor?

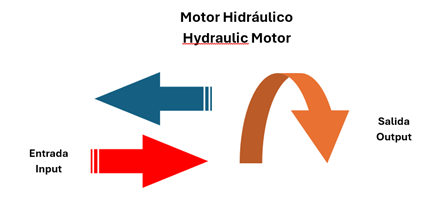

A hydraulic motor converts hydraulic energy into mechanical energy, using the flow and pressure generated by a hydraulic pump to produce rotational force or torque. Some of its main applications include hydraulic winches, sweepers, lifting systems, etc.

How does a hydraulic motor work?

Hydraulic motors receive pressurized fluid from the hydraulic pump, which drives the internal components of the motor (orbital, gear, vane, or piston motors), resulting in rotational movement. The thrust produced by this movement is used to operate various mechanical devices in industrial, agricultural, and other applications.

Types of hydraulic motors

- Orbital Motors: Capable of delivering high torque at low revolutions. These motors, based on an orbital rotor, are widely used in the textile industry, urban cleaning vehicles, agricultural machinery, etc.

- Vane Motors: They offer smooth operation, making them ideal for medium-speed and medium-torque tasks.

- Piston Motors: The bidirectional FRM motors are valued for their high efficiency and torque, making them perfect for applications requiring precise control and power.

Main differences between hydraulic pumps and motors

Although hydraulic pumps and motors are closely related, they perform opposite functions within a hydraulic system. The main differences include:

- Energy Conversion: Hydraulic pumps convert mechanical energy into hydraulic energy, while motors convert hydraulic energy back into mechanical energy.

- Fluid Flow: Pumps generate fluid flow, while motors use this flow to produce movement.

- Design: Although they appear similar, pumps and motors have different designs to fulfill their respective functions.

Featured Bezares Products:

- BE Series Gear Pumps: Ideal for a wide range of industrial applications, offering durability and efficiency.

- D and V Series Vane Pumps: Designed for medium-pressure tasks, providing smooth operation and consistent performance.

- MR and FR Series Piston Pumps: Suitable for both medium and heavy-duty applications, with the FR2 offering dual flow and the FRV 84 providing variable displacement for greater control.

Conclusion

Although these components perform opposite functions, they often work together, utilizing the vehicle engine’s power to serve the various systems required by the application.

By properly selecting the pump and/or motor based on the specific needs of each case, the application’s efficiency on the vehicle can be significantly improved, as well as its fuel consumption.