How to Choose the Most Suitable Power Take-Off (PTO) for Our Application

The Power Take-Off, as a device responsible for transferring power from the engine to an application, is one of the key components within the vehicle’s hydraulic system, and the proper functioning of the rest of the connected hydraulic equipment depends on it.

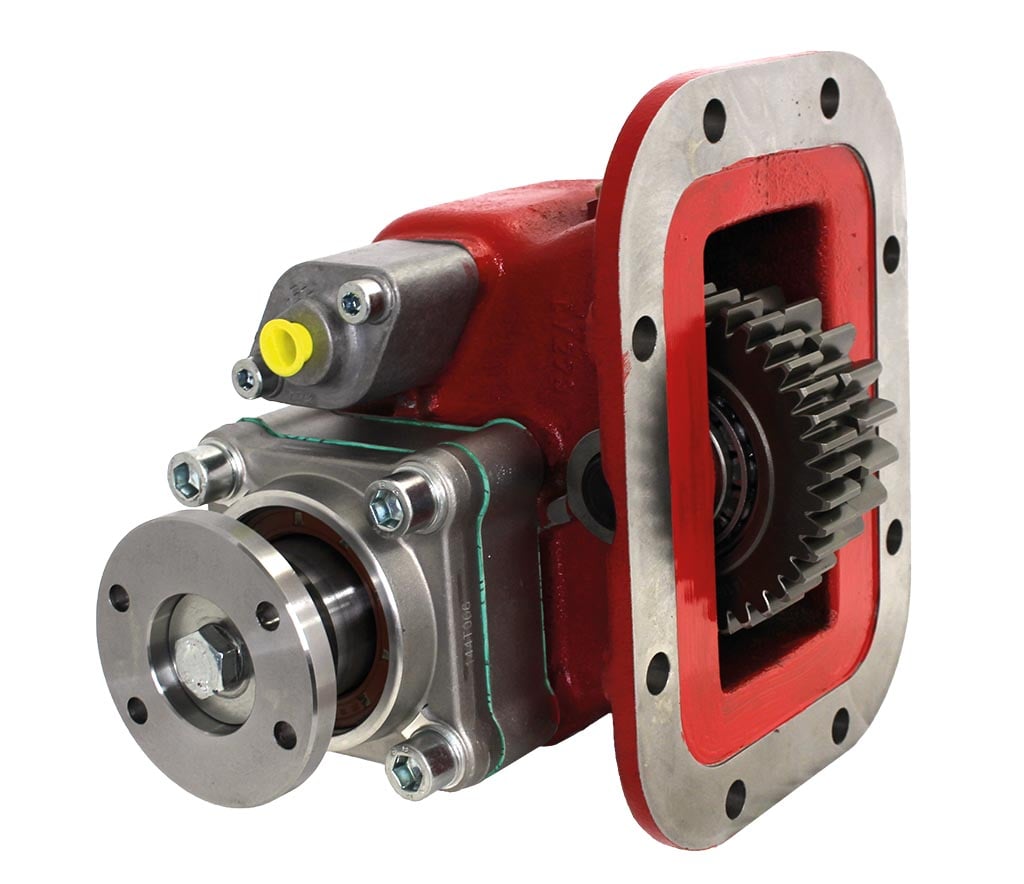

Bezares has been manufacturing a wide variety of PTOs for several decades, covering a significant portion of the most in-demand market needs. Currently, a broad selection of PTOs is offered for the most well-known gearbox models.

Choosing the right PTO is an important task, where the application’s characteristics must be considered, as it not only affects the daily performance of the hydraulic equipment but also leads to economic savings, both at the time of purchase and in fuel consumption throughout the vehicle’s life.

There are different types of PTOs depending on the installation location:

- Gearbox-Mounted PTOs

In this group, you will find products such as:- Base PTOs: Combined with various adapter kits, these can be mounted on numerous gearboxes (Mercedes, Volvo, ZF, etc.) and offer the advantage of simplifying storage and reducing delivery times for the end-user.

- Special PTOs for UNI 3 hole pumps and aluminum pumps.

- A wide variety of kits to modify the PTO’s output type, avoid possible interferences between the hydraulic pump and the vehicle, etc.

- Depending on the gearbox:

- Manual Gearboxes:

PTOs installed on these gearboxes connect and disconnect when the vehicle is stationary, in neutral, and with the clutch pressed. Once the PTO is activated, the clutch is released. - Automatic Gearboxes:

Some gearbox models allow the use of the PTO while the vehicle is in motion (using PTOs with a built-in clutch) or in stationary mode. In the latter case, the PTO connects and disconnects in a manner similar to manual gearboxes but with the gear selector in neutral mode. - Engine-Mounted PTOs

These types of PTOs are installed in the inspection aperture that some engine models include. They work continuously, regardless of whether the vehicle is stationary or moving. - Others (ePTO, splitter and transfer cases, electromagnetic clutches, etc.)

Installed in other areas of the vehicle, these offer various options and features.

- Manual Gearboxes:

Gearbox-Mounted PTOs

- It is essential to know the make and model of the gearbox.

- Each gearbox model has one or more Apertures for mounting the PTO, which can be located on the sides, bottom, rear, or even the top.

- If there are multiple Apertures, consider the available space in each and the output speed the gearbox provides in each.

- Check Bezares’ customer area for available options, comparing the torque, power, and final ratio from the technical datasheet with the parameters required for your application.

- Bezares offers different internal ratios in many PTO models, which can be considered when adjusting the selection with the hydraulic pump or connected equipment.

- There are also various output types for PTOs:

- Plate outputs in different sizes and standards (SAE/DIN).

- Outputs for direct pump coupling, with different standards (DIN, UNI, SAE, etc.).

- You can further refine your selection by choosing between different actuation types available for each case: pneumatic, mechanical, vacuum, electric, or continuous drive (without actuator).

In case of doubt, consult Bezares’ Commercial team.

Engine-Mounted PTOs

- Similarly, it is essential to know the make and model of the engine. Bezares offers PTOs and adapter kits for this type of application. Contact our Commercial department for information about the available product.

Other Types of Equipment

- ePTO:

A recent development by the R&D&I department of Bezares, focused on hydraulic equipment for the new commercial electric vehicle, has resulted in the creation of a solution that harnesses battery energy and transforms it into mechanical power for use in hydraulic applications. This new development, which features an intelligent electronic control system, allows it to adapt to different types of electric vehicles and work efficiently in most mobile hydraulic applications, thus facilitating the implementation of the commercial electric vehicle.- Complete solution

- Intelligent electronic control

- Adaptability

- Customization possibility for each application

- Single, dual, or triple-output multiplier cases:

- Splitter and transfer cases:

Connected to the vehicle’s main transmission, between the cab and the rear differential, offering many options depending on the application. - Electromagnetic clutches:

Devices connected to the engine’s crankshaft in small vehicles, allowing the mounting of different sizes of hydraulic pumps of the ISO, SAE B, and aluminum types with a keyed shaft Ø16.