Sanitizing truck in Monterrey-Mexico using a Bezares PTO 1010603 powering its hydraulic system. Another success case from our Bezares Mexico subsidiary for such important public service at this time.

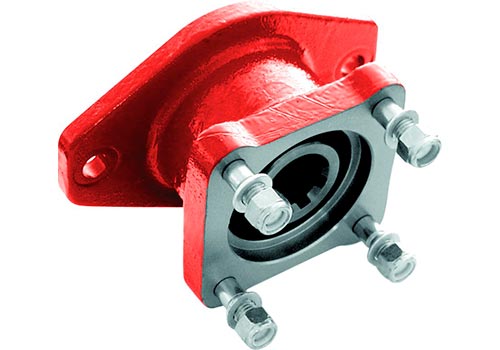

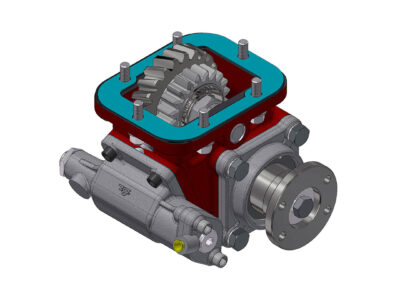

After exhaustive tests, the PTO 1220702E for Eaton transmission ES-9306A has been approved for OEM assembly in the Asian market. This new six-bolt side mount PTO, with output flange and pneumatic shifting, is based on the well-known design of our popular 1000 Series PTO. For more information, please contact our commercial department with the code 1220702E

Within the Continuous Product Improvement Program (CPIP), we have acquired a new salt spray chamber. This new equipment, manufactured by Köhler Automobiltechnik, a leading German company in the sector, allows the tests to be carried out manually or programmed and thus simulate, with greater accuracy, all the corrosion parameters on the materials as well as data recording and activity reports. In this way, the quality controls of corrosion and oxidation…

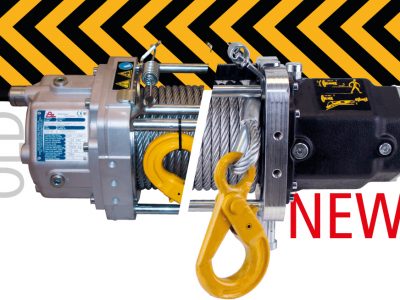

Bezares keep committed with its Continuous Product Improvement Program (CPIP), where we regularly look for customer’s feedback to apply the required improvements on our product line. The latest product to be improved under CPIP is our heavy-duty winch BZC, that has been rebranded as Mammoth to follow the same naming scheme as its medium duty, lightweight brother, the Bull winch. Apart from the branding and the new appearance, that includes…

Bezares, in its Continuous Product Improvement Program (CPIP), is streamlining its winches products offering. The first action for a simpler, intuitive winches lineup will be replacing our reduced drum “PickUp” BZC winches by our new BULL Pickup hydraulic winch. The new model offers many advantages over the well-known BZC such as a reduced mounting space while keeping its 15m of maximum rope capacity. Some example applications using these models are…