Compatible with 6-Bolt Allison & Aisin transmissions. The 3300 series PTOs feature a wide range of internal ratios, output types, and shifter options. All cast iron construction with large 12mm flange bolts to support some of the larger pumps in the market.

Features and benefits:

- Industry exclusive idler shaft with locking nut and snap ring.

- Deep gear tooth carburization for longer gear life.

- Larger flange mounting hardware provides additional support and reduces failures caused by heavy pumps – best in class.

- Industry leading Garlock gasket material provides better tear resistance and easier installation, with Viton o-ring material & shaft seals to prevent leaks.

- Symmetrical design allows for multiple configuration options and ease of installation.

- Simple and robust mechanical air shift operation.

- Quiet operational noise levels for an improved operator experience.

Typical Applications: Dump Trucks and Trailers, Walking Floor, Vacuum Pumps, and more…

CAUTION

TO PREVENT POSSIBLE INJURY:

- DO NOT go underneath the vehicle with the engine running.

- DO NOT attempt to work on an installed Power Take-Off with the engine running.

- DO NOT operate the controls of the Power Take-Off or other driven equipment from underneath the vehicle with the engine running.

- DO NOT operate the controls of the Power Take-Off or other driven equipment in any position that could result in getting caught in the moving machinery.

Make sure to block any moving or raised device that may injure a person working on or under the truck. A lever or its linkage may be accidentally moved causing movement of the device which could cause injury to a person near the device.

IMPORTANT

Because most of our Bezares Power Take–Offs and P.T.O. drive lines are sold through distributors, the product applications and the resulting degree of exposure to danger of the operators are beyond the knowledge and controls of BEZARES.

Therefore, the proper installation of the P.T.O. and its associated equipment, and the decisions of whether to install guards and/or warning signs shall be the responsibility of the designers or installers.

Since it is our major objective to show you how to get additional and more profitable miles from truck, tractor and trailer components, we want to provide you with information on the installation of 3000, 3100, and 3300 Series.

We all realize that an inadequate transmission will overwork any Power Take–Off in a very short period of time. In addition, a mismatched transmission/P.T.O. combination can result in unsatisfactory performance of the equipment right from the start.

Before you order new trucks be sure that you’re getting the right transmission/P.T.O. combination. It is of vital importance for efficient performance to have adequate power.

To help you select the proper type, size and design of P.T.O. it is advisable to discuss your specific requirements with a Bezares P.T.O. specialist. They know their products and Power Take–Offs. They can inform you about everything you need to know about power, at the right time, before you specify components.

Here are some of the questions that are relevant to the Proper Selections of a Transmission mounted Power Take–Offs.

- What is the make and model of your transmission?

- Which P.T.O. opening will be used?

- What accessory is to be driven?

- How much horsepower is required to drive the accessory?

- What is the required rotation of the P.T.O.?

- What is the required P.T.O. output shaft speed as a percent of engine speed?.

- What is the required method of shifting the P.T.O., mechanical or pneumatic?

Once all of the answer to these questions have been determined, a transmission mounted P.T.O. can be selected to meet the horsepower, speed and rotation that you require.

Check out our PTO Selection form at bezares.com/pto-selection-tool/

Having made the selection of a P.T.O., you are ready to start the installation.

- Drain the oil from the transmission and remove the PTO aperture cover plate.

- Discard the cover plate and cover plate gasket, then clean the aperture pad using a Scotch Brite Style abrasive pad.

Note: Stuff a rag in the aperture opening to prevent dirt from entering the transmission while you are cleaning it. - Install the six studs (furnished with the PTO) in the pto aperture pad.

(See also specific mounting instruction furnished with the PTO). - Place the correct number of gaskets over studs. Do not use gasketsealer between the gaskets because you may want to add or subtract gasket to obtain proper backlash. Backlash desired is .006-012 inches. Due to possible clearance issues this dimension may be difficult to obtain. The 3300 series PTO comes with a .140 metal spacer. If installing on an Allison transmission this spacer must be used. If installing on an Aisin transmission this spacer will not be used.

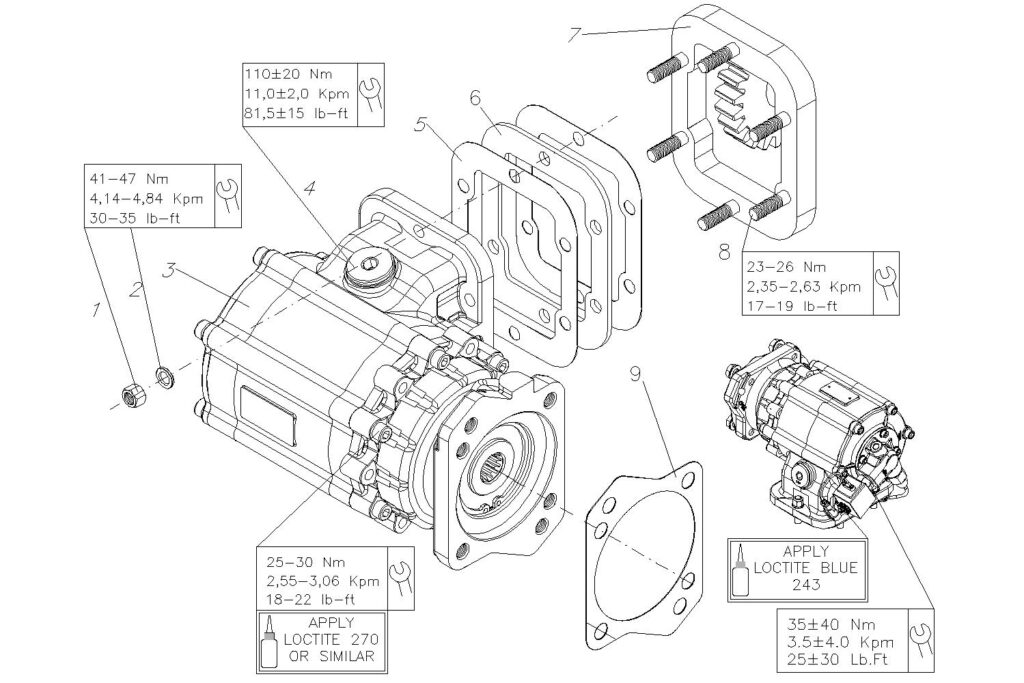

- Mount the PTO to the transmission by tightening the nuts on to the 6 studs. Torque nuts to 30-35 lb. ft.

NOTE: .140 metal spacer item #6 supplied only for Allison transmission.

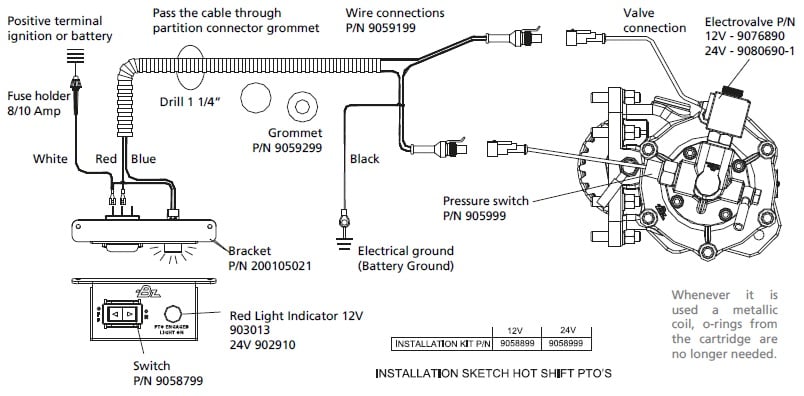

Install the cartridge and tighten to 25 – 30 Lb.ft (35 – 40 Nm).

Alternativelly, for easy installation, it can be installed on the pto before it’s being placed on

the transmission.

Note: Place a small amount of Loctite Blue (243) on the aluminium nut that

secures the coil. Do not overtighten or the threads on the nut will strip out.

Place the coil. Ensure the O-ring is in place to avoid water leaks inside the coil.

Whenever it is used a metallic coil, o-rings from the cartridge are no longer

needed.

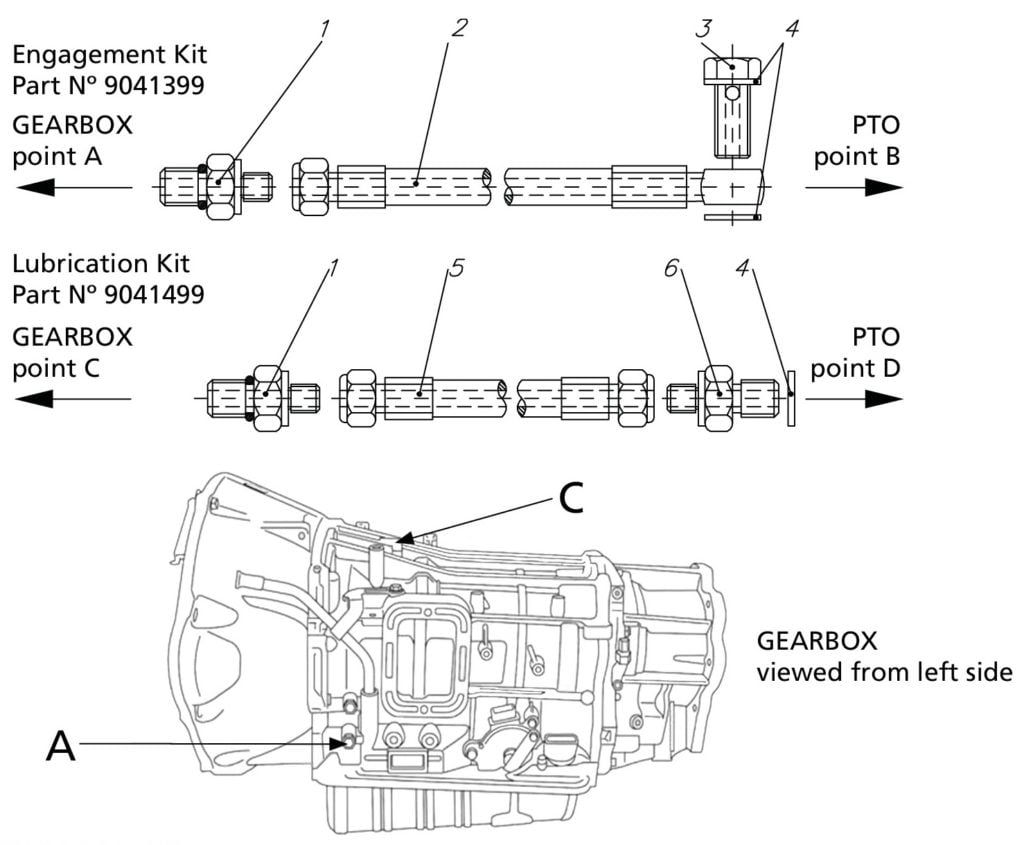

- Fitting 1/2” UNF

- Engagement hose

- Fitting M10x1

- Washer

- Lubrication hose

- Fitting 1/8” BSP

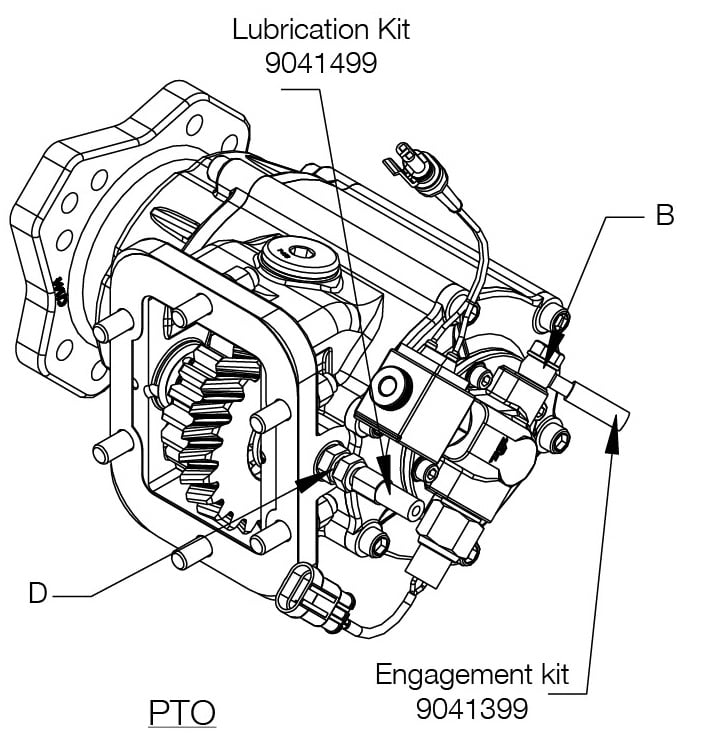

Installation method

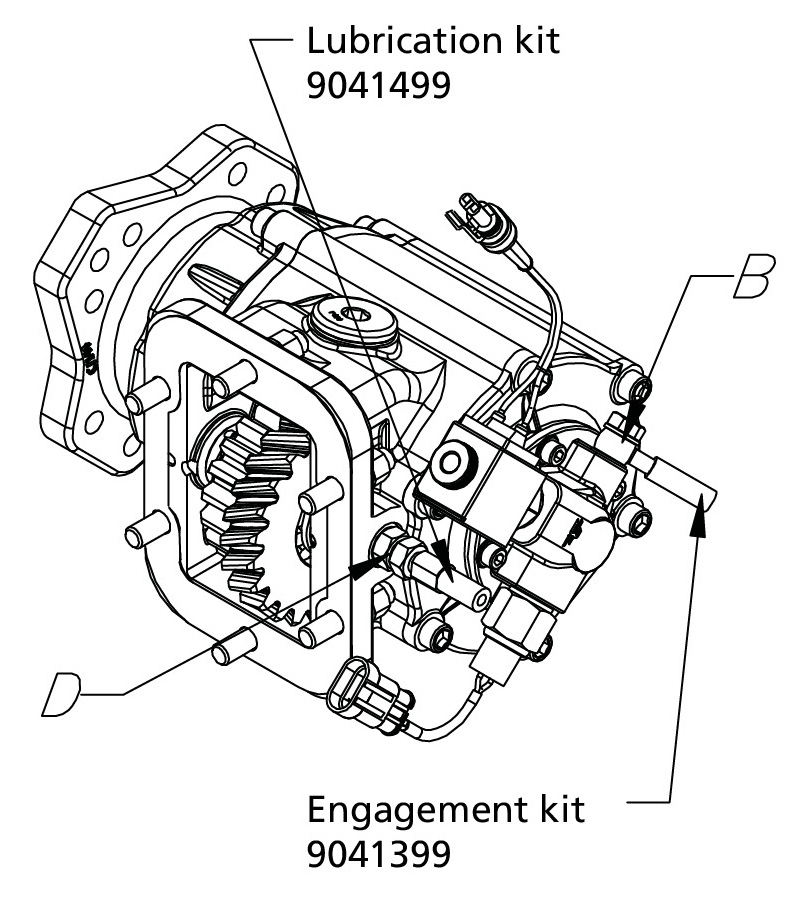

- Remove the gearbox plug in “A” and “C” position

- Remove the protection plugs placed on the PTO in “B” and “D” position.

- Fit the engagement kit (9041399) in “A” and “B” position

- Fit the lubrication kit (9041499) in “C” and “D” position.

(DODGE RAM Vehicles)

- Fitting 1/2” UNF

- Engagement hose

- Fitting M10x1

- Washer

- Lubrication hose

- Fitting 1/8” BSP

Installation method

- Remove the gearbox plug in “A”and “C” position

- Remove the protection plugs placed on the PTO in “B” and “D” position.

- Fit the engagement kit (9041399) in “A” and “B” position

- Fit the lubrication kit (9041499) in “C” and “D” position.

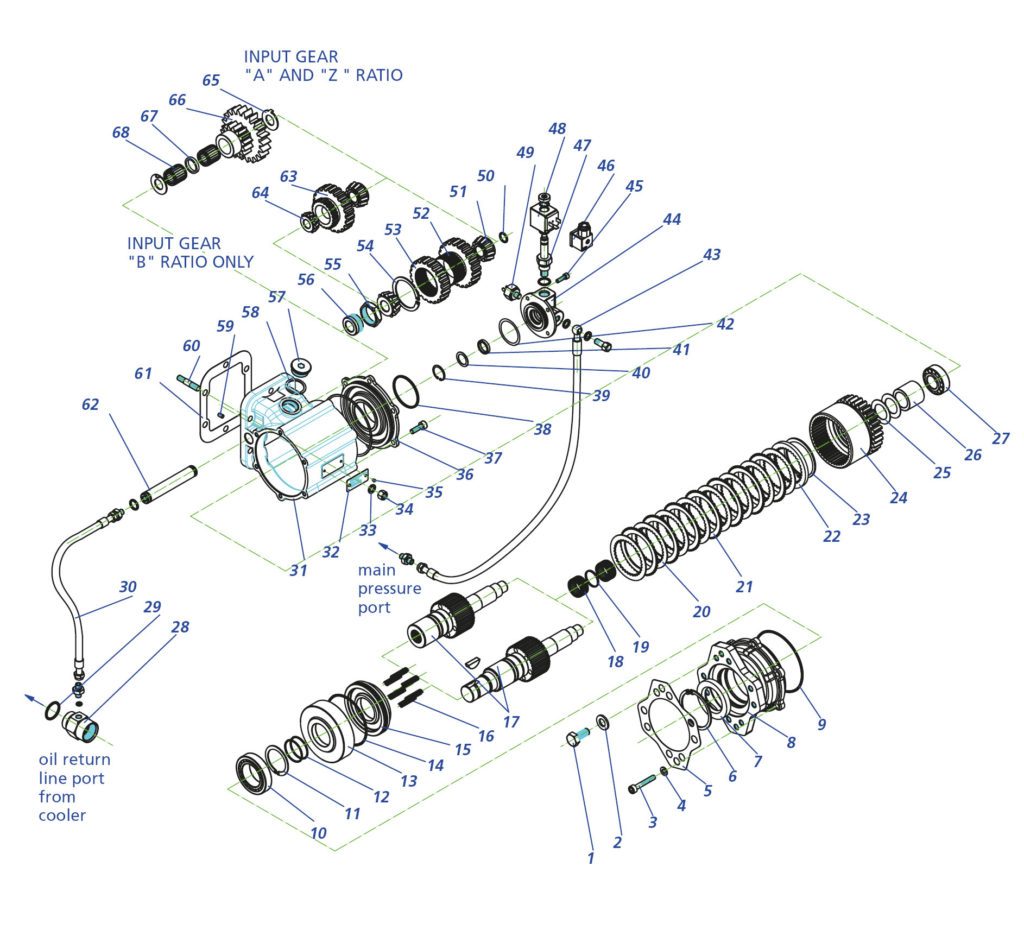

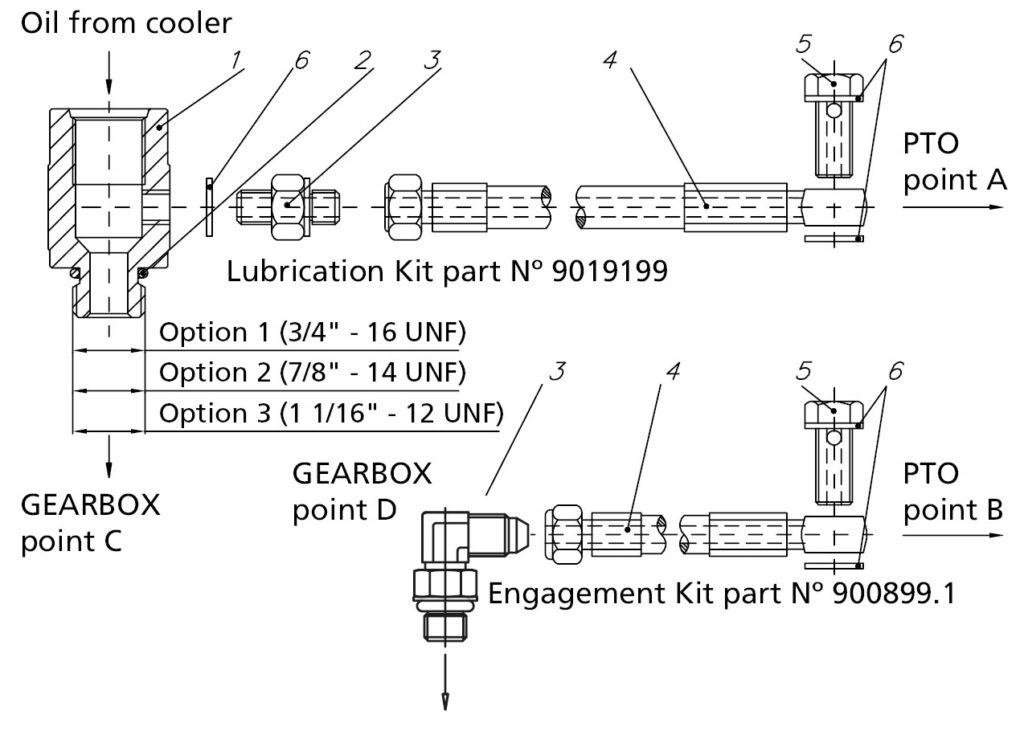

Allison 1000/2000/2400

- “T” Fitting

- O-ring

- Fitting

- Hose

- Fitting

- Washer

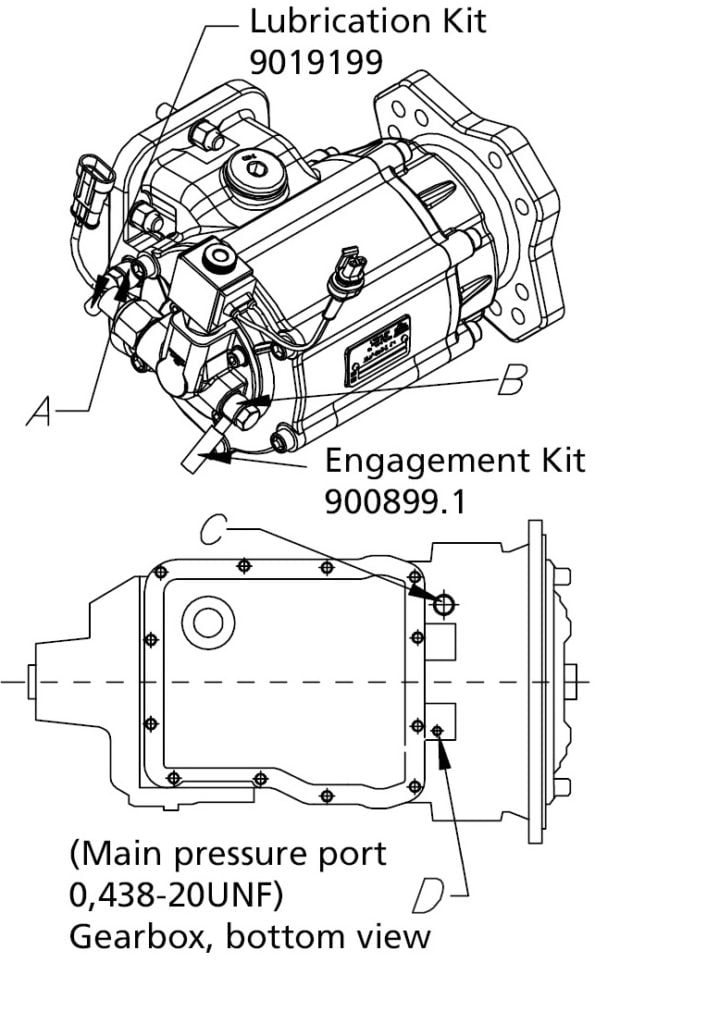

Installation method

- Install the “T” fitting (1) into the oil line returning to the transmission from cooler (point C).

- Connect the hose (9019199) to the “T” fitting (1) by means of fitting (3).

- Connect the lubrication hose to the PTO (A) position by means of the fitting (5) and washers (6).

- Fit the Pressure hose (900899.1) into the main pressure to the transmission (D) position, with the fitting (3).

- Fit the Pressure hose on the (B) position with the fitting (5) and washers (6).

* After installation of the PTO the transmission should be carefully checked for proper oil level and signs of oil leakage. The best check is conducted with the transmission at operating temperature.

CAUTION

This vehicle is equipped with a Power Take-off.

Shut engine off before working on Power Take-Off or getting below vehicle.

Consult operating instructions before using.

POWER TAKE-OFF OPERATION – VEHICLE STATIONARY

Automatic Transmission with Power Shift P.T.O’s

Engage P.T.O. with engine at idle speed. Power shift P.T.O.´s: The engine must be at idle or below 1000 rpm when the P.T.O. is engaged. See transmission manufacture´s instructions for special procedures.

IMPORTANT

Failures to follow proper shifting or operating sequences will result in premature P.T.O. failure with possible damage to other equipment.

Warning: Cold Weather Operation of Power Shift P.T.O.´s

During extreme cold weather operation [32°F (0°C) and lower], a disengaged Power

Shift Power Take-Off can momentarily transmit high torque that will cause unexpected

output shaft rotation. This is caused by the high viscosity of the transmission oil when it

is extrememly cold. As slippage occurs between the Power Take-Off clutch plates, the oil

will rapidly heat up and the viscous drag quickly decreases.

The Power Take-Off output shaft rotation could cause unexpected movement of the

driven equipment, resulting in serious personal injury, death, or equipment damage.

To avoid personal injury or equipment damage:

– Driven equipment must have separate controls.

– Driven equipment must be left in the disengaged position when not in operation.

– Driven equipment must not be operated until the vehicle is allowed to warm up.

PTO Troubleshooting

| wdt_ID | PROBLEM | REASON | CORRECTIVE ACTION | PREVENTION |

|---|---|---|---|---|

| 1 | PTO is Noisy (whines) | -insufficient mounting backlash | -remount PTO adding gaskets to achieve backlash of .006-.012” | -check and set proper backlash |

| 2 | PTO is Noisy (rattles) | -excessive mounting backlash | -remount PTO removing gaskets to achieve backlash of .006-.012” | -check and set proper backlash |

| 3 | PTO is Noisy (clicks) | -damaged/worn gear tooth | -replace damaged/worn gear | -check and set proper backlash |

| 4 | -overloading PTO | -reduce load | -review application | |

| 5 | Leaking Shaft Seal | -dirt under seal | -replace seal | -preventive maintenance |

| 6 | -damaged seal or cover | -replace seal or cover | -preventive maintenance | |

| 7 | -improperly seated seal | -replace seal | -preventive maintenance | |

| 8 | -worn shaft at seal area | -replace output shaft/seal | -preventive maintenance | |

| 9 | Leaking Output Flange | -torn flange gasket | -replace gasket | -preventive maintenance |

| 10 | -loose flange bolts | -properly torque flange bolts | -preventive maintenance | |

| 11 | -direct mount pump improperly supported | -install pump support brackets | -review application requirements | |

| 12 | Leaking Mounting Face | -torn mounting gasket | -replace mounting gasket | -preventative maintenance |

| 13 | -cracked mounting pad | -replace housing/set backlash | -proper mounting torque | |

| 14 | -broken mounting shim | -replace mounting shim/set backlash | -preventative maintenance | |

| 15 | -improper gaskets/shim used | -replace gaskets/shim | -ensure proper gaskets/shim are used | |

| 16 | Leaking Bearing/Shift | -torn gasket | -replace gasket | -preventive maintenance |

| 17 | COVER | -loose cap screws | -properly torque cap screws | -preventive maintenance |

| 18 | Cracked Housing | -insufficient backlash | -replace housing/set backlash | -check and set proper backlash |

| 19 | -unsupported direct mount pump | -replace housing/attach pump support bracket | -review application | |

| 20 | -over torque condition | -replace housing | -review application | |

| 21 | -foreign object between gears | -replace housing/gears | -preventive maintenance | |

| 22 | -impact with external object | -replace housing | -install protection/avoid impacts | |

| 23 | -shock load/cold relief pressure | -replace housing | -allow oil to warm before loading | |

| 24 | PTO Failure | -broken/damaged parts | -inspect/replace damaged parts | -preventive maintenance |

| 25 | -driveshaft problem | -check phasing, angle, and slip of driveshaft | -preventive maintenance | |

| 26 | -worn/damaged driveshaft components | -repair/replace driveshaft | -preventive maintenance | |

| 27 | PTO Does Not Engage/ Disengage (wire shift) | -worn/damaged shift control | -repair/replace components | -preventive maintenance |

| 28 | -loose/missing linkage/attachments | -adjust/replace components | -preventive maintenance | |

| 29 | -worn/damaged cable | -repair/replace components | -preventive maintenance | |

| 30 | PTO Does Not Engage/ Disengage (air shift) | -lack of air pressure | -ensure pressure exceeds 100psi/governor cut-in | -preventive maintenance |

| 31 | -shifter damaged | -replace shifter | -install protection/avoid impacts | |

| 32 | -shifter piston leaking | -replace shifter seals | -preventive maintenance | |

| 33 | -shifter piston does not move | -check for contaminates in air cylinder | -preventive maintenance | |

| 34 | -contaminated air lines | -clean air systems | -preventive maintenance | |

| 35 | -worn/damaged shift control | -repair/replace components | -preventive maintenance | |

| 36 | PTO Does Not Engage/ Disengage (all) | -shift fork not in shift collar | -check/reinstall shift cover | -preventive maintenance |

| 37 | -internal gears do not mesh | -check for internal debris/damage | -preventive maintenance | |

| 38 | -improper shifting | -adjust vehicle clutch | -review transmission manual |