This hydraulic pump is a bent – axis type pump with fixed displacement, developed under the design of spherical head pistons. This gives to the pump a very high performance and high pressure ratings on a long life span unit with European standard assemblies. Therefore, this pump can be mounted directly in most of PTO’s in the world.

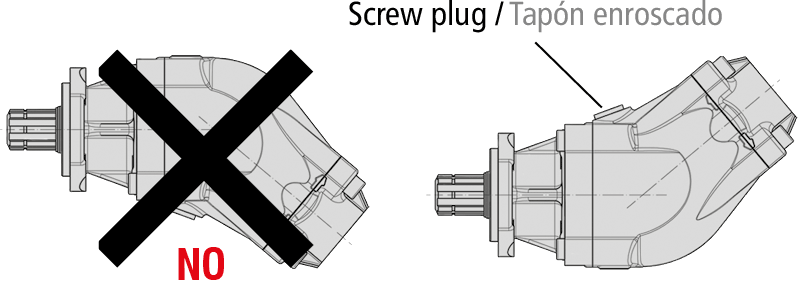

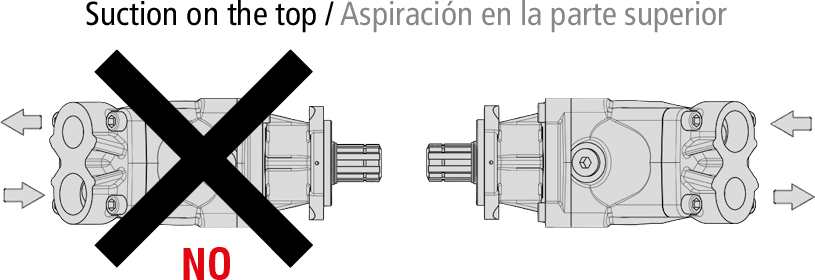

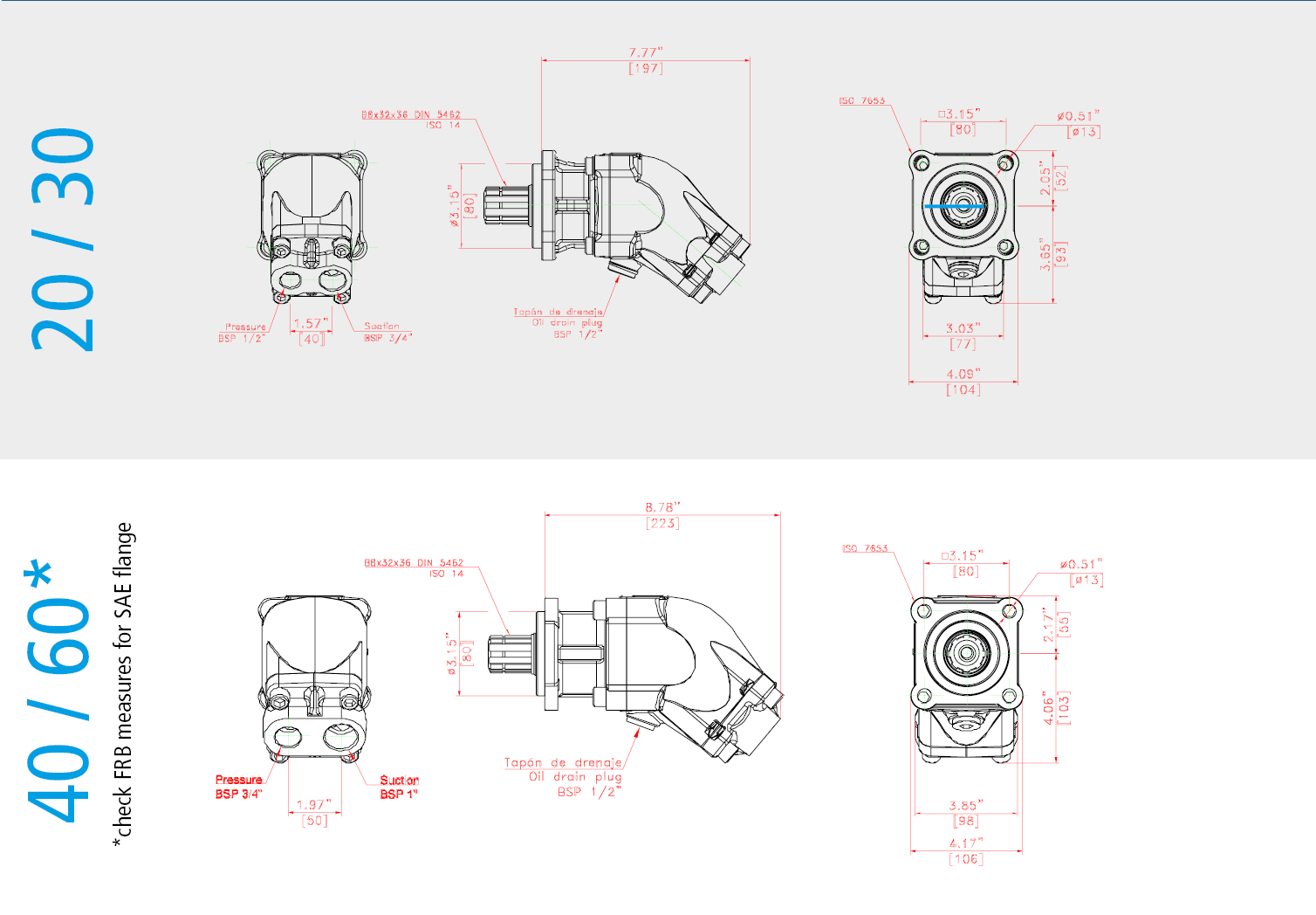

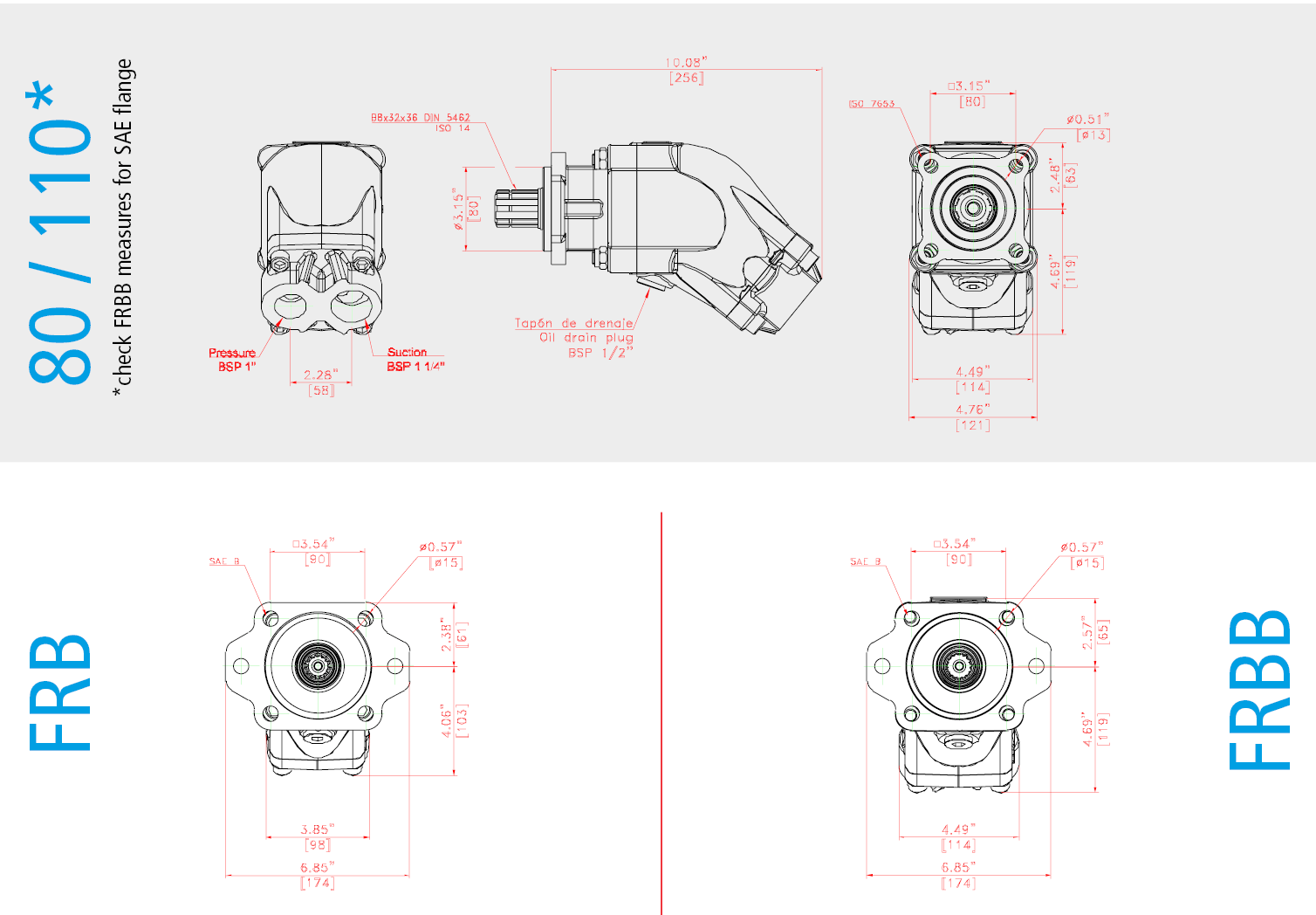

FR pumps are constructed with 4-hole coupling flanges, ISO 7653 compliant, for direct fitting to the PTO. These FR pumps can be driven by a truck PTO, by a diesel engine (using an elastic coupling), or by a prop (cardan) shaft. Should the pump be installed above the level of the tank, special measures must be taken to ensure that the pump is full of oil at all times (Fig. 1 and Fig.2).

INITIAL START UP

Apply grease at the shaft previous to the PTO installation. Clean the entire hydraulic system before filling with oil. Fill the pump with oil through the suction and pressure ports. lf the pump is fitted above the tank, it must also be filled through the filler cap (Fig. 1). FR pumps are self-priming and have an internal drainage system. Start the pump with no pressure load at a moderaTe speed (500 rpm). lf no oil flow is detected after 15 seconds, stop the pump and check that the suction line is properly installed, the circuit of the suction fine is open, and the pump rotation direction is correct.

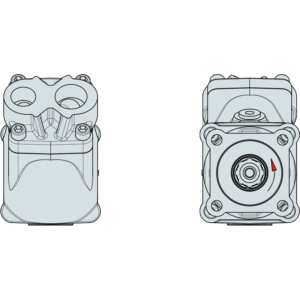

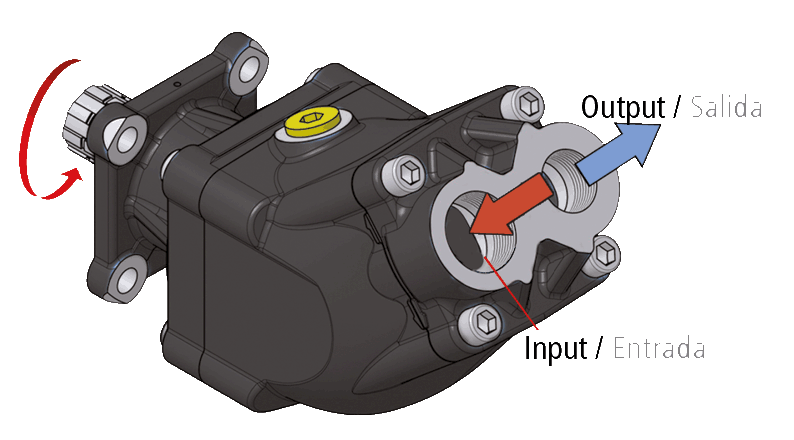

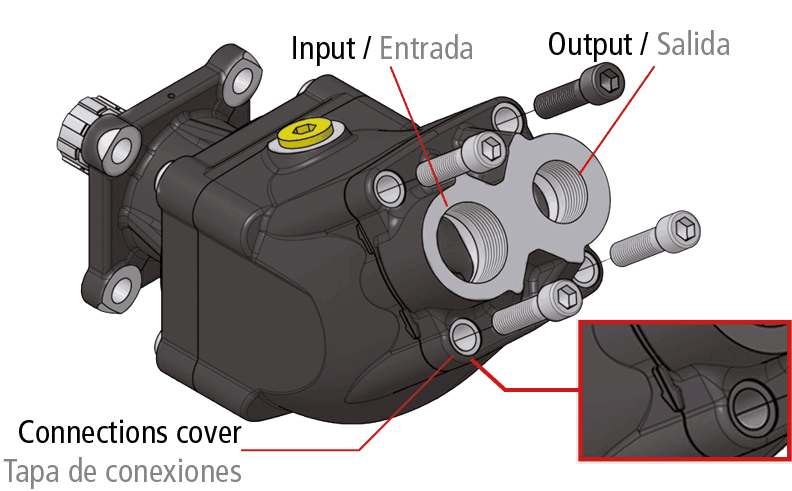

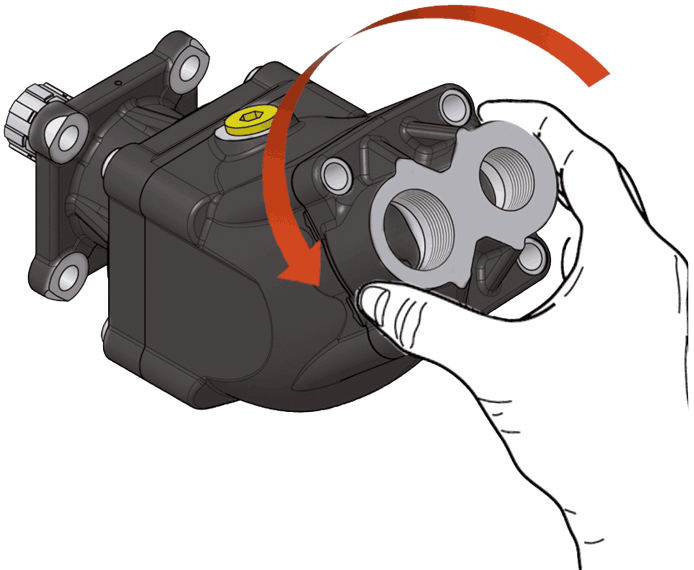

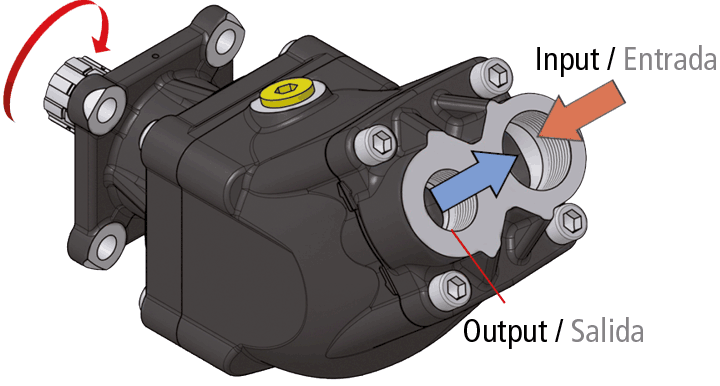

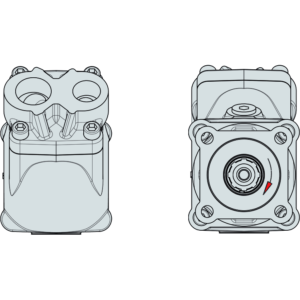

Choosing the direction of rotation

Clockwise rotating pump.

To change the direction of rotation remove the 4 screws and, keeping the distributor body close to the pump, rotate it by 180º

Arrow indicate rotation direction

Tighten the 4 screws at:

M12 – 95-100 Nm (70-74 lb.Ft)

M10 – 65-70 Nm (48-51 Lb.Ft)

Be sure not to break the gasket.

During this operation the pump cover must not move away from the pump body more than 2mm.

Anti-clockwise rotating pump.

| wdt_ID | PUMP | ROTATION | THREAD | 20 | 30 | 40 | 50 | 60 | 80 | 110 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | ISO (FR) | CW | ISO | 5040606 | 5040806 | 5041006 | 5047506 | 5041206 | 5051706 | 5041606 |

| 2 | ISO (FR) | CCW | ISO | 5040706 | 5040906 | 5041106 | 5048106 | 5041306 | 5051806 | 5041706 |

| 3 | ISO (FR) | CW | SAE | - | - | 5042206 | - | 5042406 | 5042606 | 5042806 |

| 4 | ISO (FR) | CCW | SAE | - | - | 5042306 | - | 5042506 | 5042706 | 5042906 |

| 5 | SAE (FRB / FRBB) | CW | SAE | - | - | 5045406 | - | 5045606 | 5045806 | 5046006 |

| 6 | SAE (FRB / FRBB) | CCW | SAE | - | - | 5045306 | - | 5045506 | 5045706 | 5045906 |

| 7 | Displacement cm3/rev (Cuin / rev) | 19 (1.16) | 30.4 (1.85) | 39.38 | 49.47 (3) | 59.86 | 78.79 | 109.47 | ||

| 8 | Pressure (bar / PSI) | max. cont | 350 (5076) | 350 (5076) | 350 | 350 (5076) | 350 | 370 | 350 | |

| 9 | Pressure (bar / PSI) | max. peak (5sec) | 400 (5800) | 400 (5800) | 400 | 400 (5800) | 400 | 420 | 400 | |

| 10 | Speed r.p.m. | max. cont | 2200 | 2000 | 2000 | 1700 | 1700 | 1500 | 1400 | |

| 11 | Speed r.p.m. | max. peak (5sec) | 2800 | 2600 | 2600 | 2300 | 2300 | 2000 | 1900 | |

| 12 | Power kW (HP) | max. cont | 21 | 30 | 37 | 40 | 45 | 54 | 71 | |

| 13 | Power kW (HP) | max. peak (5sec) | 28 | 39 | 50 | 52 | 58 | 66 | 93 | |

| 14 | Weight kg (Kg) | ISO | 7.6 | 7.7 | 9.5 | 10 | 10 | 15 | 15 | |

| 15 | Weight kg (Kg) | SAE | 9.97 | 10.76 | 15.6 | 15.6 |

| wdt_ID | Pump | Details | 45 | 80 | 110 |

|---|---|---|---|---|---|

| 5 | Displacement cm3/rev (Cuin / rev) | 44.02 (2.69) | 78.79 (4.76) | 123 (7.5) | |

| 6 | Pressure (bar / PSI) | max. cont | 250 (3626) | 250 (3626) | 250 (3626) |

| 7 | Pressure (bar / PSI) | max. peak (5sec) | 300 (4351) | 300 (4351) | 300 (4351) |

| 8 | Speed r.p.m. | max. cont | 1400 | 1500 | 1300 |

| 9 | Speed r.p.m. | max. peak (5sec) | 1600 | 1900 | 1700 |

| 10 | Power kW (HP) | max. cont | 24 | 45 | 65 |

| 11 | Power kW (HP) | max. peak (5sec) | 32 | 66 | 90 |

| 12 | Weight kg (Lb) | 7.7 | 10 | 15 |

| wdt_ID | Motor | Details | 40 | 60 | 80 | 110 |

|---|---|---|---|---|---|---|

| 5 | Displacement cm3/rev (Cuin / rev) | 39.38 | 59.86 | 78.79 | 109.47 (6.68) | |

| 6 | Pressure (bar / PSI) | max. cont | 250 (3626) | 250 (3626) | 250 (3626) | 250 (3626) |

| 7 | Pressure (bar / PSI) | max. peak (5sec) | 300 (4351) | 300 (4351) | 300 (4351) | 300 (4351) |

| 8 | Speed r.p.m. | max. cont | 2000 | 1700 | 1500 | 1400 |

| 9 | Speed r.p.m. | max. peak (5sec) | 2500 | 2200 | 2000 | 1800 |

| 10 | Power kW (HP) | max. cont | 27 | 34 | 41 | 52 |

| 11 | Power kW (HP) | max. peak (5sec) | 37 | 44 | 54 | 67 |

| 12 | Weight kg (Lb) | 9.5 | 10 | 15 | 15 |

Use mineral based oils for hydraulic systems. To select the correct viscosity, the operating temperature of the oil, measured in the tank should be considered. At operating temperature, the viscosity of the oil should be within the range of 20-35 cSt. The oil in the housing of the pump (leakage oil) is typically at a higher temperature than the tank temperature. Maximum temperature at any point in the system must be less than 90ºC. If this temperature is exceeded in the housing of the pump, special shaft seals should be used.

Please, use the following guidelines to choose the correct oil grade:

20-40ºC: VG 22 – VG 32.

40-60ºC: VG 32 – VG 46

60-90ºC: VG 68 – VG 100

The finer the filtration, the better the achieved purity grade of the fluid, and the longer the life of the pump. Purity grades of 18/13 (ISO 4406) or 9 (NAS 1638) should be guaranteed by the filtration system. We suggest a return filter, (avoid a filter in the suction line) with a mesh from 10 µm (high pressure and/or contaminated environment) to 25 µm (low pressure and clean environment). The flow capacity of the filter should be at least twice the pump flow under the operating conditions.

Direction of rotation of the pump can be changed removing the four screws of the connection cover, to rotate it 180º. An arrow is drawn up in both housing and cover indicating the direction of rotation. With no other indication of the customer, all the pumps are supplied with clockwise rotation.