What is and how to choose a Hydraulic pump

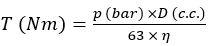

A hydrostatic transmission pump, commonly called a hydraulic pump, is a positive displacement machine and its mission is to transform mechanical energy into hydraulic, based on the Pascal Principle. This Principle is based on the fact that, when exerting a pressure or push on a fluid like oil (which is considered incompressible), it is transmitted equally in all directions.

Taking advantage of this principle, hydraulic actuators, depending on the pressure and displacement surface (eg surface of a piston), will transmit the force necessary to move the application.

Turning the pump drive shaft causes the internal components responsible for the suction and delivery of the oil to be moved, by varying the volume at each turn, called displacement, with a minimum loss and regardless of the pressure of the system.

Put more simply, the pump delivers an oil flow to the system and through a distributor with pressure limiting, the direction, the effort and the speed with which the actuator of the application is moved, which is usually a cylinder (tipper, crane) or a hydraulic motor (winch, winch, wheel, head or other).

They are usually found in mobile applications such as industrial vehicles, civil works or maintenance, as well as industrial applications such as elevators, presses, machine tools and process machinery.

The assembly and actuation of the pump is direct through a power take-off coupled to the vehicle’s gearbox, although an indirect hydrostatic transmission can also be mounted, or by coupling and electric motor (AC / DC) or combustion.

The most frequent types of pumps are manufactured Bezares, s.a. (Spain), such as piston pumps, pallets and gears, being one of the few factories in the world that produces the 3 types and also manufactures power sockets and distributors.

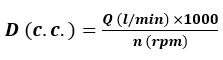

Displacement of the pump: Knowing the displacement will let you know the size of pump needed.

Q = Flow required by application (l / min)

n = RPM output (rpm motor x PTO internal ratio)

Example: if we have a tap that rotates at 1000rpm and we need the flow rate to be 60l / min, we would need a 60c.c.

On the contrary, if we have a pump of 60c.c. and an electric motor rotating at 1,500rpm, the pump would provide a theoretical flow rate of 90l / min.

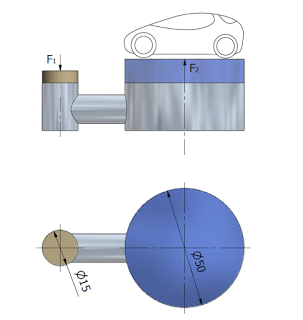

Required power in the power take-off or in the motor for the application:

p = Pressure (bar)

η= yield (eg If it is 95%, the value will be

Example: if we need about 60l / min and the application requests a pressure of 250bar, the power we would consume would be about 35 c.v. with a 95% performance piston pump.

In the case of electric motor mounting, the operating time must be kept in mind.

In turn, if we have a motor of 35 cv, we can clear the value of the pressure, to know the maximum value of work in bar.

Required torque in the PTO for the application:

Q = Flow required by the application (L / min)

n = Revolutions at the inlet of the PTO

Example: if we have a pump of 60c.c. and the application requests a pressure of 250bar, the torque to be transmitted to the shaft would be 250Nm with a gear pump with a 95% efficiency.

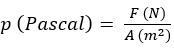

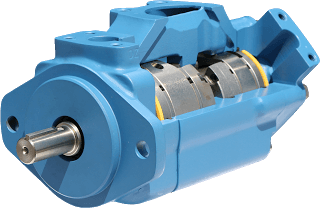

Finally, recall the Pascal Principle of Pressure:

, or of more practical application:

, or of more practical application:

And if we know the working pressure and the useful surface of the actuator:

It is very important to keep in mind that the required oil volume should be approximately 3 times the required flow rate and control the variables such as the operating time and the oil temperature.

Bidirectional, aluminum body, low noise, with internal drainag

Types of assembly: ISO / UNI / SAE A.Types of assembly: ISO / UNI / SAE A.

Bidirectional, cast steel body, with internal drainage

Types of assembly: ISO / UNI / SAE B.

Side and rear ports with BSP, SAE or NPT threads

Flow rates: 50 ÷ 115 cc / rev. P1 200 ÷ 290 barMounting types: ISO / SAE B / SAE BB.Side and rear ports with BSP, SAE or NPT threadsREINFORCED BELS VERSION WITH DOUBLE SHAFT SUPPORT BEARING.

Piston Pumps

Variable flow pumps

(*) The load sensing system accurately provides the required flow rate at every moment, drastically reducing energy consumption and generating heat, resulting in smoother and quieter system operation. All of this results in a reduced environmental impact.

Vane pumps are unidirectional units with great versatility and quiet operation, with easily replaceable cartridges. The configuration of the output ports can be customized according to the needs of the customer. Wide variety of flow and axes. The most used are:

VQ – Flow rates: 8 ÷ 240 cc / rev. P1 125 ÷ 175 barALSO DOUBLE FLOW VERSIONS AND PASSING AXLE VERSIONS FOR DOUBLE OR TRIPLE PUMPS.

DT6GC – Flow rates: 11 ÷ 100 cc / rev. P1 240 barDOUBLE FLOW VERSIONS: DT6GCC

VS – low rates: 8 ÷ 240 cc / rev. P1 125 ÷ 175 barALSO DOUBLE FLOW VERSIONS AND PASSING AXLE VERSIONS FOR DOUBLE OR TRIPLE PUMPS.

DT6C – Flow rates: 11 ÷ 100 cc / rev. P1 160 ÷ 240 barDOUBLE FLOW VERSIONS: DT6CC

DT6D – Flow rates: 48 ÷ 190 cc / rev. P1 80 ÷ 210 barDOUBLE FLOW VERSIONS: DT6DCTRIPLE FLOW VERSION: DT6DCC

DT6E – Flow rates: 132 ÷ 270 cc / rev. P1 75 ÷ 210 barDOUBLE FLOW VERSIONS: DT6EC AND DT6EDTRIPLE FLOW VERSION: DT6EDC

For additional information, please contact our Commercial department