We are proud to announce important improvements in the quality control process of for vane pumps and motors, among them, the new test bench, specially designed for production and laboratory tests in which pressures up to 420 bar and flow rates up tp 450 l/min will be achieved. The new test bench will be equipped with a 202 kW engine and will reach 3000 rpm to satisfy the most demanding tests. A new software will manage in a more…

Bezares will participate in the International Agricultural Machinery Fair (FIMA) 2018, which will take place at the Feria de Zaragoza facilities from 20 to 24 February 2018. We will present our latest releases as well as our TDZ product line for the agricultural sector, where the last generation machinery linked to this sector will become the undisputed protagonist. In its 40th edition, the International Fair of Agricultural Machinery 2018 already…

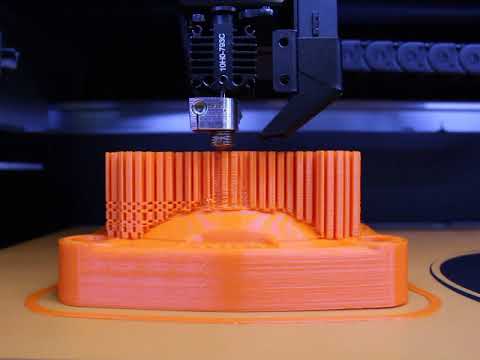

Continuing our goal of continuous improvement of our products, quality control and production processes, Bezares incorporates the new DT600 3d printer from DynamicalTool. The DynamicalTool DT600 printer offers a professional 3D printing system of last generation, with 2 independent heads, precision mechanics and different work materials, thus offering a precision and speed of printing quite superior to the system previously used. This printer supposes the simplification of the work of…

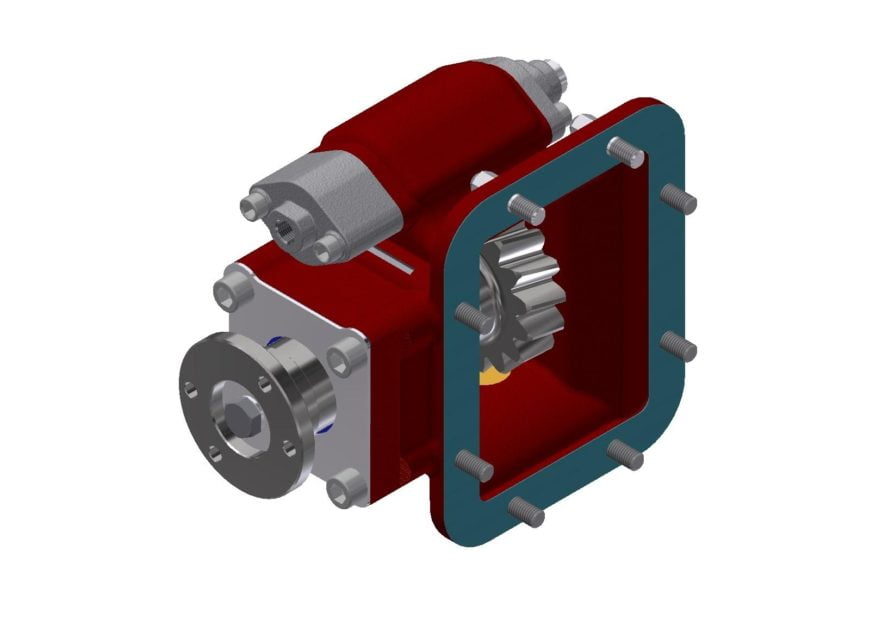

Extending our range of products, we present our new constant mesh PTO, with one gear, to be mounted on the left side opening of the gearbox Isuzu MEB9. This PTO is available with pneumatic actuator, with output flange. Isuzu MEB9 is a 9-speed manual gearbox, capable of developing a high torque. Combined with the 6NX1-TCS engine, it achieves a greater efficiency in the consumption and a lower level of noise.…

Bezares presents the new range of aluminum oil tanks MBM in 160 and 200 l. In these new tanks, the return connectors on both sides have been removed in order to improve the mounting options in those chassis where the space is very limited. On the rear side, next to the suction connector a drain port was added. Also the front level indicator was replaced for a new fill cap…